Ultrafiltration Membranes

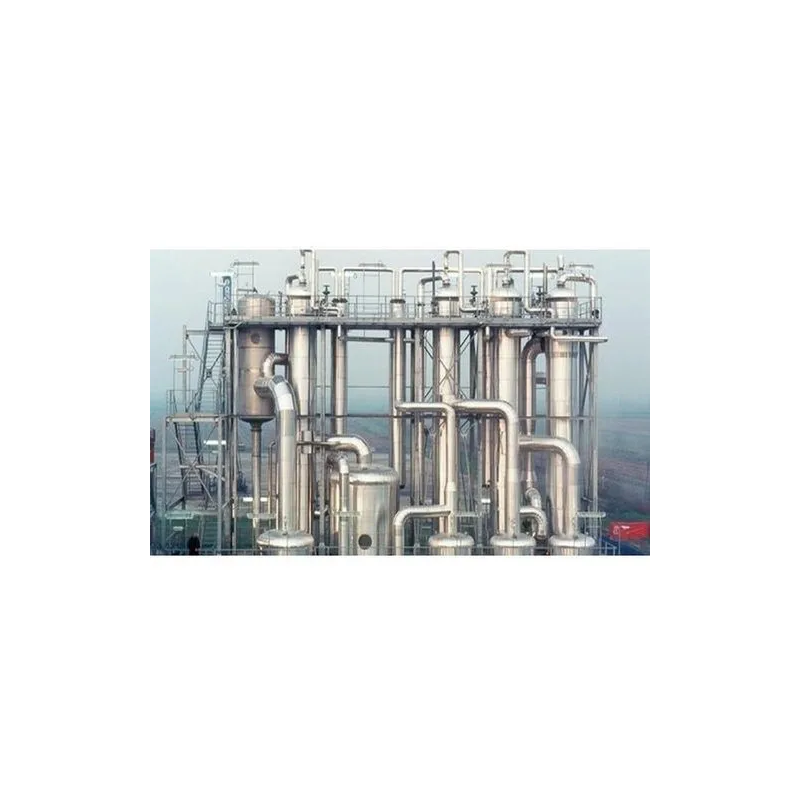

Zero Liquid Discharge System Capacity 1000 KLD

Quantity

Reference ACAKO Category Zero Liquid Discharge System

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Zero Liquid Discharge System Capacity 1000 KLD

Reference ACAKO Category Zero Liquid Discharge System

Specifications

| Country of Origin | India |

|---|---|

| Warranty | 1 Year |

| Automation Grade | Semi-Automatic |

| Installation Type | Prefabricated |

| Water Source | Industrial Effluent |

| Capacity (KLD) | 1000 KLD |

| Control Module | Available |

| Treatment Technique | Clarifier |

| Inlet Flow Rate(m3/day) | 1000 m3/day |

Key Features

- Easy installation

- High Durability

- High performance

Product Details

Zero Liquid Discharge System Capacity 1000 KLD, Zero Liquid Discharge (ZLD) is a treatment process designed to remove all liquid waste from a system. The focus of ZLD is to reduce wastewater economically and produce clean water that is suitable for reuse (e.g. irrigation), thereby saving money and being beneficial to the environment. ZLD systems employ advanced wastewater/desalination treatment technologies to purify and recycle virtually all of the wastewater produced.Water is a scarce resource and due to Urbanization and Globalization water usage will increase in the coming years. Industries like power, oil, and gas, pharmaceuticals, and chemicals generate a large volume of wastewater which contains solid waste, organic waste, toxic and non-toxic chemicals which further affects the environment. In fact, many governments and industries have come up with initiatives to reduce water waste by installing ZLD, which in turn will reduce water wastage, and help them attain a sustainable environment.Water is a precious resource and its demand is growing exponentially. Water quality and environmental regulations are continuously evolving, requiring industries to review their water management strategies. Zero Liquid Discharge (ZLD) is increasingly being adopted by industries. However, all of these approaches have limitations due to high capital, maintenance, and/or operational costs. This publication discusses the basics of ZLD as well as the role of reverse osmosis (RO), and membrane technology in ZLD applications. The paper also reviews key applications, their challenges and cost-effective resolution approaches through the use of RO. To fully utilize all the industrial water produced, or that would otherwise go to waste streams, zero liquid discharge (ZLD) is necessary. Not all systems are created equal and in addition to upgrades may need a custom ZLD design to suit your application. A ZLD treatment system utilizes advanced technological water treatment processes to remove dissolved and suspended contaminants from industrial waste streams. This technology then concentrates and crystallizes the contaminants into solid waste so nearly 100% of your original water can be recycled or reused for boilers, cooling towers, process feeds, etc. In fact, this recycling process allows for a significant reduction in blowdown and chemical usage, which will further reduce your sludge volumes and decrease operating costs significantly.

- Low Maintenance

Other products from this brand

Ultrafiltration Membranes

Thickness Gauge

$163

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Recommended Products

Zero Liquid Discharge System

Zero Liquid Discharge System

Zero Liquid Discharge System

Zero Liquid Discharge System

Zero Liquid Discharge System

Zero Liquid Discharge System

Zero Liquid Discharge System

Zero Liquid Discharge System

Zero Liquid Discharge System

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon