Ultrafiltration Membranes

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

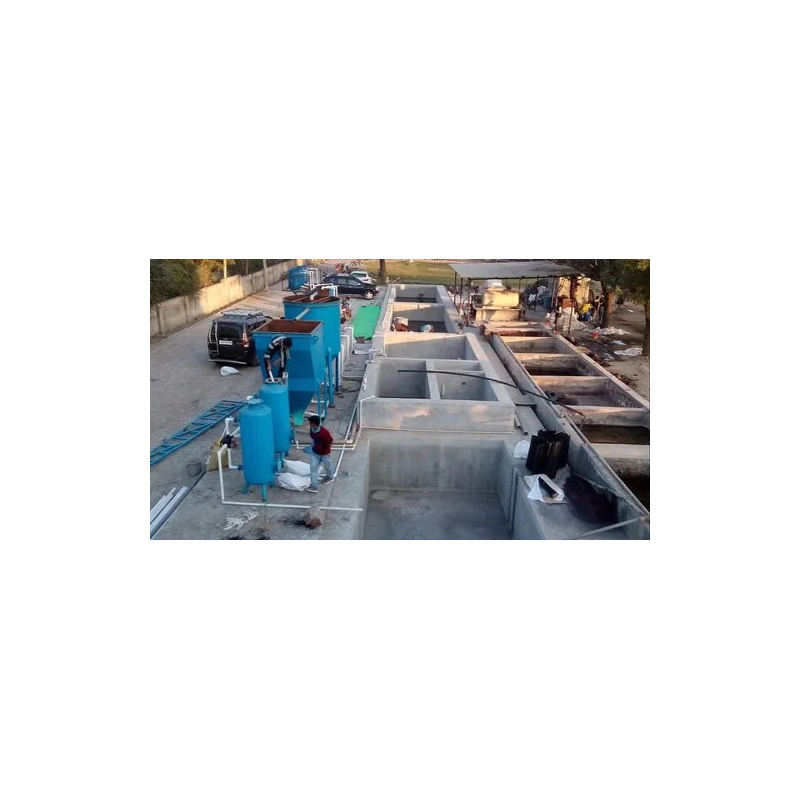

Zero Liquid Discharge System 500 KLD

Reference ABWYH Category Zero Liquid Discharge System

Specifications

| Application | Chemical /Petroleum Industry |

|---|---|

| Country of Origin | India |

| Warranty | 1 Year |

| Automation Grade | Semi-Automatic |

| Material of Construction | Mild Steel |

| Water Source | Industrial Effluent |

| Treatment Stages | Primary Treatment Preliminary Treatment Secondary Treatment |

| Capacity (KLD/MLD) | 500 KLD |

| Inlet Flow Rate(m3/day or m3/hr) | 500 m3/day |

Key Features

- Lowered waste volumes decrease the cost associated with waste management

- Recycle water on site, lowering water acquisition costs and risk. Recycling on-site can also result in less treatment needs, versus treating to meet stringent environmental discharge standards

Product Details

Zero Liquid Discharge System 500 KLD, The power industry as well as oil & gas, chemical, petrochemicals, mining, and other industries generate large volumes of waste water that must be managed. Commonly these wastewaters are discharged via a plant outfall to a surface water body, an evaporation pond, or in some cases deep well injected. However, there are growing environmental concerns regarding such discharge practices, which has resulted in the development of Zero Liquid Discharge (ZLD) processes.Zero liquid discharge can be defined broadly as a process for maximum recovery of water from a wastewater source that would otherwise be discharged. This water is beneficially reused and the salts and other solids contained in the wastewater are produced and generally disposed of in a landfill.

- Reduce trucks associated with off-site wastewater disposal, and their associated greenhouse gas impact and community road incident risk.

- Improved environmental performance, and regulatory risk profile for future permitting

Other products from this brand

Ultrafiltration Membranes

Thickness Gauge

$163

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Recommended Products

Zero Liquid Discharge System

Zero Liquid Discharge System

Zero Liquid Discharge System

Zero Liquid Discharge System

Zero Liquid Discharge System

Zero Liquid Discharge System

Zero Liquid Discharge System

Zero Liquid Discharge System

Zero Liquid Discharge System

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon