Ultrafiltration Membranes

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

- Genuine Products

- Global Shipping

- Secured Payments

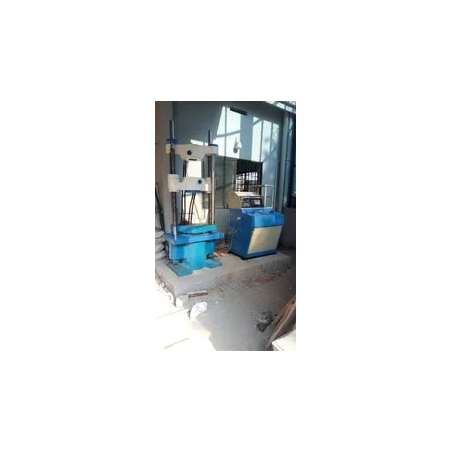

Computerized Universal Testing Machine Phase 3

Quantity

Specifications

| Voltage | 415V 50 / 60 Hz A.c. |

|---|---|

| Capacity | 100 kN |

| Phase | 3PH |

| Machine Weight | 1300 kg |

| Machine Type | Computerized |

Key Features

- Easy installation

- High performance

- High Durability

Reference ACDQI Category Universal Testing Machine (UTM)

Product Details

The base has a hydraulic cylinder at its center and two main screws at both ends. The middle cross head is mounted on screws through the main nuts. The middle cross head can be moved up or down through chain transmission and geared motor to adjust the initial tensile/compression clearance. Inside the base of the machine, a hydraulic cylinder is tested in which the piston is placed on the piston, rests an assembly of upper, lower cross head, and two columns. The individually lapped cylinder piston assembly ensures smooth axial force with minimum friction.Control Panel :The hydraulic circuit consists of a hydraulic power pack that has a directly driven radial plunger pump that gives a continuous non-pulsating flow of oil pressure up to 250 bar a pressure compensated needle-type flow control valve is obtained with help of valves. Optionally this can be controlled from an electronic system.Loading Rate / Straining Rate Control :This is a superfine controlling system that controls the loading rate / straining rate as per commands from the electronic machine control system. FINE UTM Software can send the loading rate/straining rate to an electronic system for fully automatic testing.Operation :A tension test is conducted by gripping the test specimen in the upper and middle crosshead. Compression, Bending, Transverse, Shear, and Hardness tests are conducted between the middle and lower crosshead by using appropriate fixtures. The rapid adjustment of the middle crosshead facilitates easy fixing of tensile / Compression specimens of different lengths.Hydraulic controls are through hand-operated valves, ergonomically placed for ease of control. Optionally valves can be controlled from the electronic control system. Adequate safeties for overload and overtravel are incorporated and an emergency switch is provided.

- Easy maintenance

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

Other Products from this Brand

Ultrafiltration Membranes

Thickness Gauge

$163

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Turbine Blower

Industrial Valves

$6

Recommended Products

Universal Testing Machine (UTM)

Universal Testing Machine (UTM)

Universal Testing Machine (UTM)

Universal Testing Machine (UTM)

Universal Testing Machine (UTM)

Universal Testing Machine (UTM)

Universal Testing Machine (UTM)

Universal Testing Machine (UTM)

Universal Testing Machine (UTM)

Universal Testing Machine (UTM)

Universal Testing Machine (UTM)

Universal Testing Machine (UTM)