Ultrafiltration Membranes

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

- Genuine Products

- Global Shipping

- Secured Payments

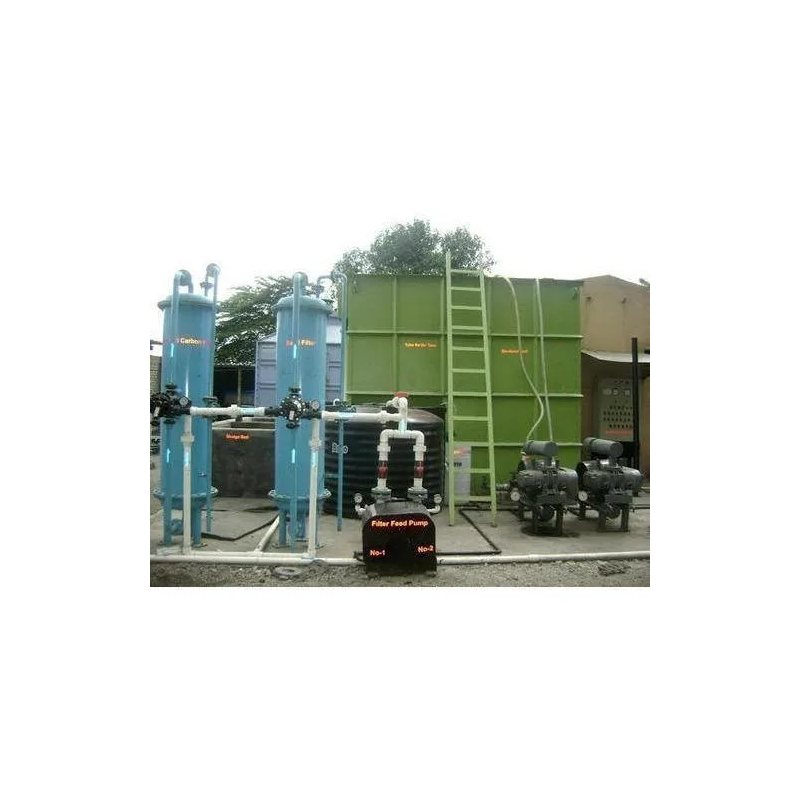

Industrial Sewage Treatment Plant Capacity 100 KLD

Quantity

Specifications

| Country of Origin | Made in India |

|---|---|

| Automation Grade | Automatic |

| Installation Type | Prefabricated |

| Water Source | Industrial sewage |

| Application Industry | All types of industries |

| Secondary Treatment Technology | Mixed Bed Bio Reactor(MBBR) |

| Treatment Stages | Secondary Treatment |

| Air Blower Count | 2 Blowers |

| Air Blower Power | 0.5 kW |

| Capacity (KLD/MLD) | 100 KLD |

| Feed Flow Rate(m3/day or m3/hr) | 101-500 m3/day |

Key Features

- Efficient filtration process

Reference ACAHE Category Sewage Treatment Plant

Product Details

Industrial Sewage Treatment Plant Capacity 100 KLD, Sewage contains a huge amount of organic matter which is toxic. Microorganisms are widely used in sewage treatment plants for removing this toxic organic matter. A sewage or wastewater treatment plant consists of two stages.Primary TreatmentIt involves the removal of large or small-sized components in the wastewater through physical processes.Biological Treatment:Aerobic microorganisms are inoculated into the sewage treatment plant. These microbes utilize the organic components of the sewage and reduce toxicity. This can be measured by BOD (Biological oxygen demand).After the biological treatment, the sludge is pumped from the treatment plant into a large tank. This large tank consists of anaerobic bacteria which lead to the digestion of sludge. During digestion, biogas is produced and it is used as an energy source. Hence, Sewage treatment plant design and sewage management play a crucial role in the maintenance of human welfare.Energy generationMicroorganisms that are involved in the production of energy are called microbial fuel cells. Microbial fuel cells are used to generate a variety of energy sources like biogas and electricity. Agricultural waste, manure, and domestic waste are used as raw materials for the generation of biogas. Biogas generation is done in a large concrete tank which is called a biogas plant.Biomasses (Biowastes) are collected at the biogas plant and the slurry is fed. Biomasses are rich in organic matter. Some of the bacteria can grow anaerobically inside the biogas plant. These bacteria can digest the biomasses which are present in the slurry and sewage. During digestion, a huge amount of mixture of gasses is released inside the tank. The mixture of these gases is called biogas. Biogas is removed from the biogas plant through a separate outlet.Microbial fuel cells are also used to generate electricity from wastewater. Microbial fuel cells utilize the organic matter from the wastewater treatment plant. During digestion, organic matter is converted into a simple molecule and releases carbon dioxide and electrons. Those electrons are absorbed by the electrode and used as the source of electricity.

- Sturdy construction

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

Other Products from this Brand

Ultrafiltration Membranes

Thickness Gauge

$163

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Turbine Blower

Industrial Valves

$6

Recommended Products

Sewage Treatment Plant

Sewage Treatment Plant

Sewage Treatment Plant

Sewage Treatment Plant

Sewage Treatment Plant

Sewage Treatment Plant

Sewage Treatment Plant

Sewage Treatment Plant

Sewage Treatment Plant

Sewage Treatment Plant

Sewage Treatment Plant

Sewage Treatment Plant