Ultrafiltration Membranes

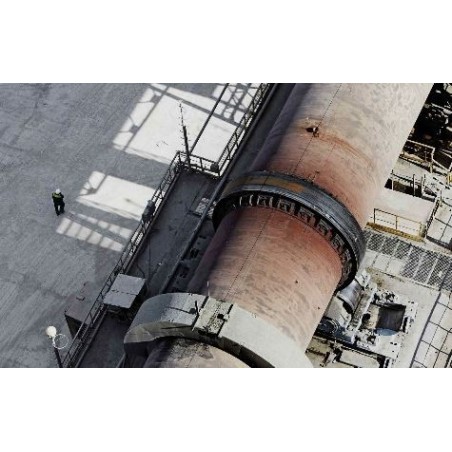

Rotary Kiln For Industrial Length to Diam Ratio 14 to 16

Quantity

Reference ABNYL Category Rotary Kiln

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

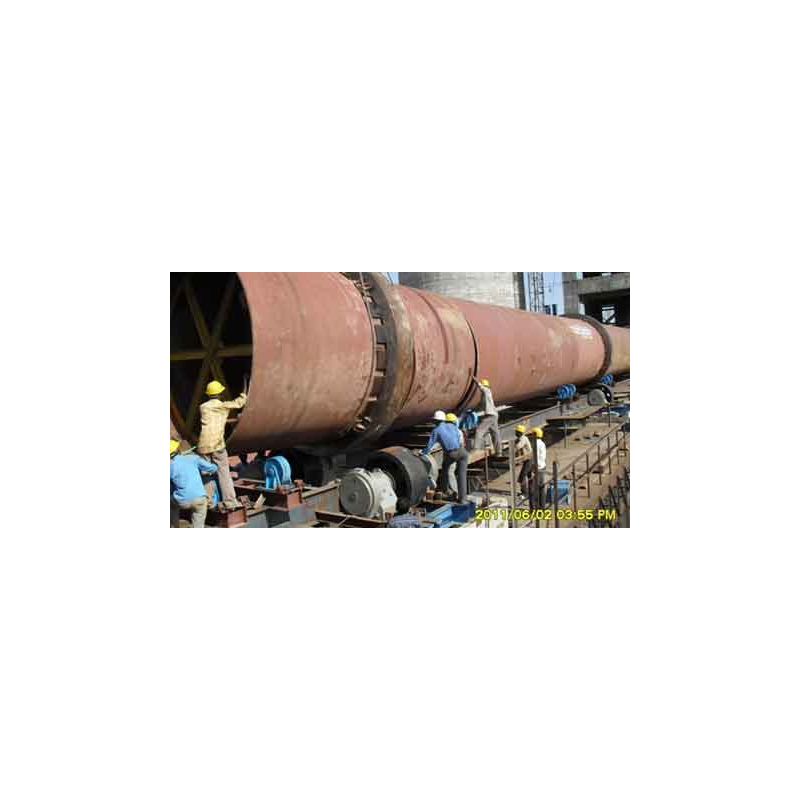

Rotary Kiln For Industrial Length to Diam Ratio 14 to 16

Reference ABNYL Category Rotary Kiln

Specifications

| Size | Rotary Kiln For Industrial| Length to Diameter Ratio 14 to 16 |

|---|---|

| SUCCESSFUL INSTALLATION IN | Cement Aluminate Cement Limestone & Lime sludge Pet coke Calcination Minerals i.e. Bauxite and Iron Ore Sponge Iron |

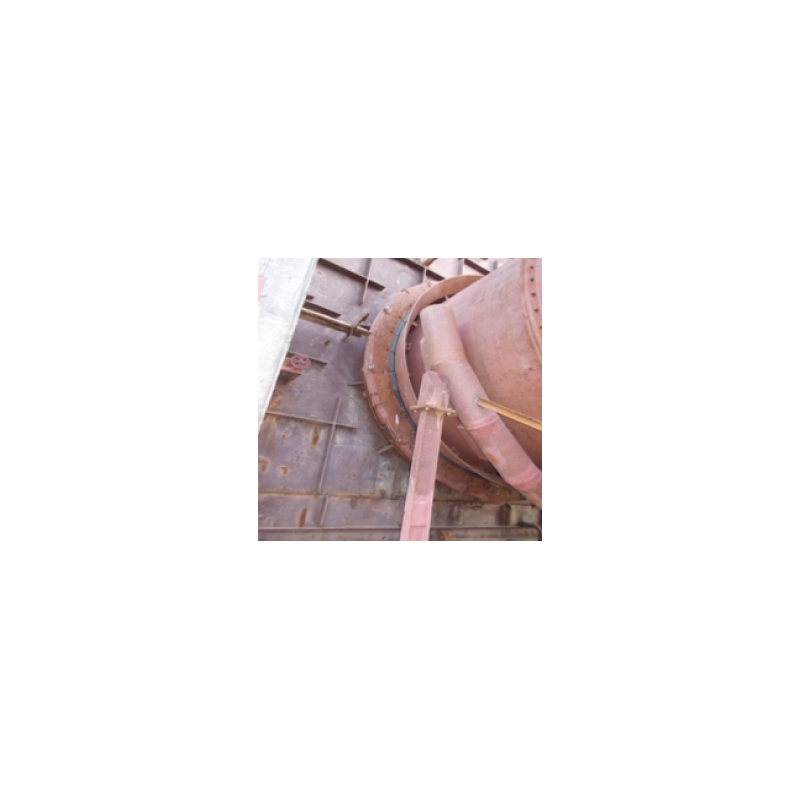

| KILN INLET SEAL | Kiln inlet seal will be of friction type ring. Two nos. rings| carrying wear shoe segments on face| with one ring being rotating with Kiln| slide on face to face. The wear shoes are lubricated by high temperature grease. The sliding ring have pneumatic cylinders| distributed equally on the periphery| which always keep both the shoe rings of primary seal in contact| even during and upward-downward movement. |

| KILN DISCHARGE SEAL | Discharge end seal is made up of radially placed overlapping segmented graphite blocks. This allows movement of shell in radial and axial direction while effectively sealing. |

| NOSE RING FAN | The discharge end is provided with another annular shell around with spacer flexible element. The cooling air is blown in this annular gap by cooling air fan using distribution nozzle ring made of pipes. |

Key Features

- Better inlet and outlet sealing to ensure minimum false air entry

- Hydraulic thruster provides control to the Kiln axial movement.

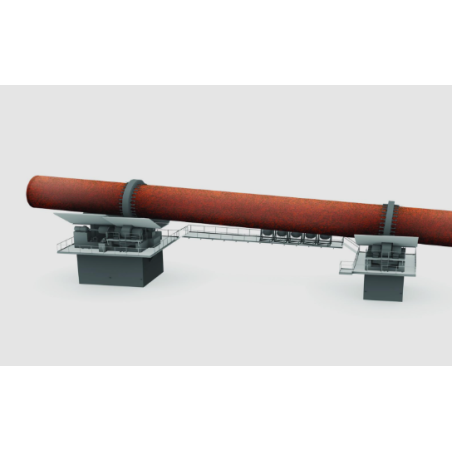

- Three support roller stations are provided for better distribution of forces on shell.

Product Details

Rotary Kiln For Industrial, Length to Diameter Ratio 14 to 16 Rotary kiln is a rotating cylindrical vessel which is used for drying, calcination and sintering in a continuous process with the use of hot gases. The hot gases may be generated in an external furnace or by a flame inside the kiln. Our cement rotary kiln and sponge iron rotary kiln has been developed for performing drying, calcination and sintering work in a continuous process. Widely used for cement, pet coke calcination, sponge iron and other materials, it uses hot gases for the operation. Integrated with variable speed drive, process automation and instrumentation, this kiln ensures optimum operational control. In addition to technology, its design features better inlet and outlet sealing to ensure minimum false air entry.HIGHLIGHTSLength to Diameter Ratio 14 to 16.Specific Heat Consumption (for Clinker) - 695 to 750 Kcal/Kg.Main drive variable speed driveDesigned to use alternative fuels also.Process automation and instrumentation for optimum operational control.

- Ensures optimal safety with regard to material elasticity at operating temperature. Throat adjuster is provided to optimize Kiln / Calciner fuel.

Other products from this brand

Ultrafiltration Membranes

Thickness Gauge

$163

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Recommended Products

Rotary Kiln

Rotary Kiln

Rotary Kiln

Rotary Kiln

Rotary Kiln

Rotary Kiln

Rotary Kiln

Rotary Kiln

Rotary Kiln

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon