Ultrafiltration Membranes

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

- Genuine Products

- Global Shipping

- Secured Payments

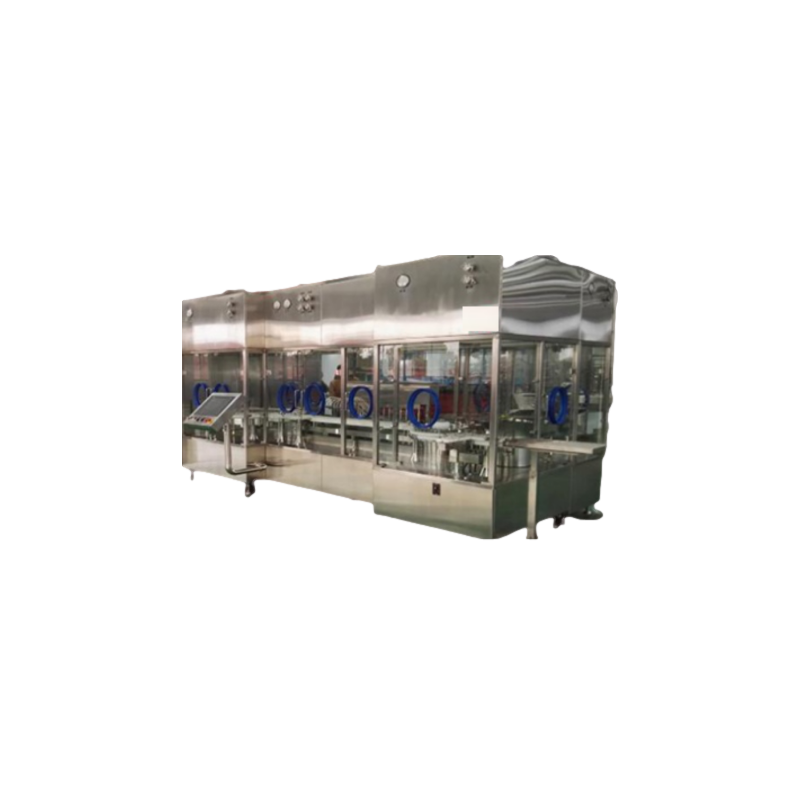

Pre-Filled Syringe Packaging Line

Quantity

Specifications

| Suitable for | Aqueous substance / Viscous substance with the help of change parts. |

|---|---|

| Usage/Application | Industrial |

| Power Supply | Three Phase 440 V 50 Hz (Stabilized) |

| Working Height | 850 mm 50 mm |

| Air consumption | 5 CFM |

| Filling station | 1 No. 2 No. 5 No. & 10 Nos. |

| Filling Capacity | 0.5 ml onwards |

| Output / minute | Up to 100 PFS per minute @ 1 ml (Output may vary based on nature of the filling substance and volume) |

| Dosing Accuracy | 0.01 |

| Air Supply | 6 to 8 Kg / cm |

| Nitrogen supply | 5 CFM pressure (Customer scope) |

Key Features

- Syringe Filling Machine & Stoppering Machine loaded on Stainless Steel in-feed hopper. A prefilled syringe manufacturing process machine tray can directly be loaded onto the PFS machine. Duly filled & stoppered syringes delivered on outfeed collection tray without hand touch.

Reference ACFWV Category Packing Machine

Product Details

Pre-Filled Syringe Packaging Line Consist of Pre-Filled Syringe Filling, Pre-Filled Syringe Stoppering, Pre-Filled Syringe Rod Inserting, and Pre-Filled Syringe Sticker Labeling Machine. Pre-Filled Syringe Filling Machine and Dental Cartridge Filling Machine, Pre Filled Syringe Stoppering Machine, Pre Filled Syringe Sealing Machine, Pre Filled Syringe Plunger Insertion Machine, and Pre Filled Syringe Labeling Machine consist of the main structure covered polycarbonate cabinet and SS 304 pipe, laminar airflow, filling head with individual servo motor, out-feed collection tray, vacuum system, pneumatic components, and electrical panel, AC Drive, PLC & HMI.The machine is manufactured or developed accordance with GMP standards.The structure is made of SS 304 or cladded with SS 304.Rigid vibration free construction for trouble free performance.Machine with out-feed trays for collection of syringe tub.All contact parts SS 316L and non-contact parts are SS 304.Machine suitable for different syringe size with help of change part and depends on characteristic of liquid.Servo with syringes synchronized system for filling Accuracy.Filling volume set with touch screen HMI.Pneumatically controlled Stoppering mechanism.Very easy & accurate electronic based volume setting of different pre-fill syringes.Zero Dripping filling stations.Diving system with the design of timer belt and Stepper Motor/pneumatic Control which has no Vibration and very smooth kind of filling, filling material must be Fill Centrally in the Syringe.Design of Nozzles and adjustment of flow rate is very useful for filling with minimum Air Bubble / foaming in the Syringes.Low air machine stop sensor.LAF stop machine stop sensor.Door interlocking system.

- Easy installation

- Low maintenance

- Compact size

Other Products from this Brand

Ultrafiltration Membranes

Thickness Gauge

₹17,843

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Turbine Blower

Industrial Valves

₹700

Recommended Products

Packing Machine

Packing Machine

Packing Machine

Packing Machine

Packing Machine

Packing Machine

Packing Machine

Packing Machine

Packing Machine

Packing Machine

Packing Machine

Packing Machine