Ultrafiltration Membranes

Membrane Bioreactor Filtration Systems 5KLD-10 MLD

Quantity

Reference AAJPX Category Membrane Bioreactors

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Membrane Bioreactor Filtration Systems 5KLD-10 MLD

Reference AAJPX Category Membrane Bioreactors

Specifications

| Type | Effluent Treatment| Sewage Treatment| Waste Water Treatment| Water Purification for Drinking |

|---|---|

| Capacity | 5KLD-10 MLD |

| Automation Grade | Manual| Semi-Automatic| Automatic Semi-Automatic| Fully Automatic| Manual |

| Water Source | River Water| Industrial Effluent| Municipal Sewage| Borewell Water| Commercial Waste Water| Industrial Wastewater |

| Installation Service | Yes |

| Water Source Type | Industrial Wastewater |

| Applicable Industry | Hospital| Chemical/Petroleum| Pharmaceutical| Slaughter House| Automobile |

| Capacity Inlet Flow Rate (cubic meter/hour) | 500 m3/hour| 5000 m3/hour| 2000 m3/hour| 10000 m3/hour| 100 m3/hour| 1000 m3/hour500 m3/hour| 5000 m3/hour| 2000 m3/hour| 10000 m3/hour| 100 m3/hour| 1000 m3/hour |

Key Features

- Better control of biological activity

- Effluent that is free of bacteria and pathogens

- Smaller foot print

- Biodegradation efficiency enhanced 20%-40%

- Short Hydraulic Residence Time (HRT) & Long Sludge Residence Time (SRT)

Product Details

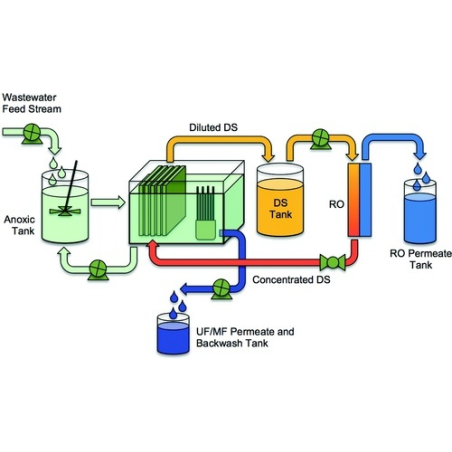

Membrane Bioreactor Filtration Systems that we manufacture and supply are water treatment systems that integrate biological degradation of wastewater, using the membrane filtration technique. Set up of the MBR plant incorporates a bioreactor and membrane filtration. One unit processes wastewater treatment thereby replacing, and in some cases supplementing the solids separation function of secondary clarification and effluent filtration. This results in a greater possibility of elimination of the secondary clarification and operation at higher MLSS concentration.Other details:MBR system is the combination of traditional Activated Sludge Treatment and membrane technologyThe design criteria of the system are based on the traditional way of Activated Sludge Treatment principleMBR modules are immersed and located in the air blow tank/aeration basin (biological reactor tank)The clear water is pumped (sucked) out from the MBR modulesThis eliminates the need for secondary clarified

- Activated sludge increase by 2-3 times

- Higher organic loading rates

- Convenient management with automatic control system

- Adopt high strength polypropylene material membrane, easy cleaning, long lifespan to 5-7 years

Other products from this brand

Ultrafiltration Membranes

Thickness Gauge

$163

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Recommended Products

Membrane Bioreactors

Membrane Bioreactors

Membrane Bioreactors

Membrane Bioreactors

Membrane Bioreactors

Membrane Bioreactors

Membrane Bioreactors

Membrane Bioreactors

Membrane Bioreactors

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon