Ultrafiltration Membranes

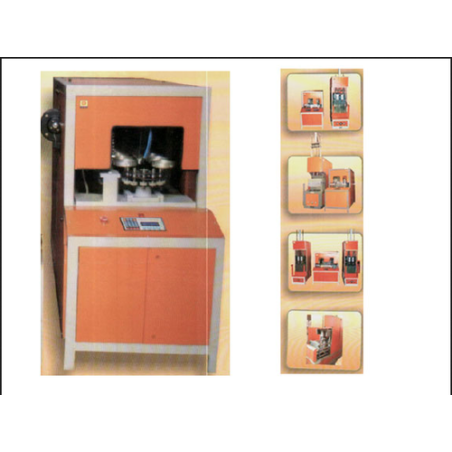

Automatic Vial Filling Machine & Rubber Bunging Machine HMPLPREVFB

Quantity

Reference ACFUZ Category Jar Filling Machine

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Automatic Vial Filling Machine & Rubber Bunging Machine HMPLPREVFB

Reference ACFUZ Category Jar Filling Machine

Specifications

| Model | HMPLPREVFB |

|---|---|

| Dimensions | 2700mm (L) x 1500mm (W)x 2000 mm(H) Approx. |

| Net Weight | 650 Kg Approx. |

| Usage/Application | Industrial |

| Power Supply | 3 Phase + Neutral + Earthing/ 415 V AC/ 50 Hz |

| Power Consumption | 2.5 kw |

| Working Height | 875 50 mm Adjustable |

| Output Speed | 30 to 100 Vials/Minute (Depend upon nature of liquid & size of vials) |

| Air Supply | 4 to 6 Kg/Cm |

| Vials Diameter | 25 mm to 55 mm |

| Rubber Bung Size | 13 mm 20 mm & 32 mm |

| Filling Volume | 2 ml to 30 ml |

Key Features

- Most reliable & proven mechanical components such as FESTO make pneumatics & CE certified electrical/electronic such as Bonfiglioli make AC motor, Allen Bradley make drives, PLC & HMI Touch screen, Sensors, MCB's, relay etc

- The machine is made compact & versatile as per GMP norms The structure is made out of MS cladding with SS 304 Rigid vibration free construction for trouble free performance The contact parts such as filling nozzle, bung disc are made of SS316 L The Pharma grade silicon tubes are used for filling & CIP/SIP Easy to clean the base of the machine There is a special feature called PRIME which is useful to suck the filling material from storage tank to nozzle end very quickly. Moreover this facility is useful to clean the filling line (silicon tubes) as well as filling peristaltic pump in both the directions

Product Details

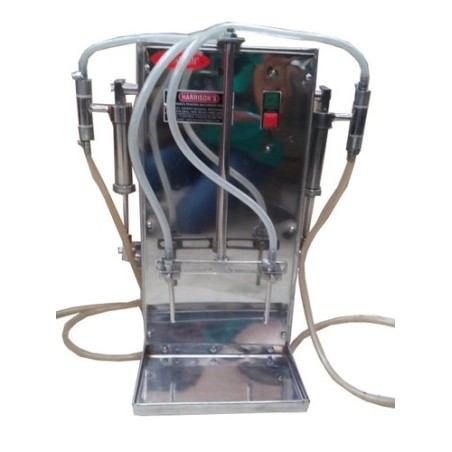

The Automatic Vial Filling Machine and Rubber Bunging Machine consists of main structure covered with SS cabinet safety acrylic cover, laminar air flow, in-feed turntable Machine, peristaltic pump filling Machine, Delrin Slate conveyor, out-feed turn table, vibrator bowl & chute for rubber stopper, pneumatic components and electrical panel, AC Drive, PLC & HMI. Automatic Injection Vial Filling Machine, Automatic Pharmaceutical Vial Filling Machine, Automatic Vial Cap Sealing Machine, Automatic Vials Filling & Capping Machine, Automatic Filling and Sealing Machine For Vial, Automatic Vial Filling Equipment, Automatic Vial Filling Line For Pharma, Automatic Vial Filling Machine, Automatic Liquid Filling Machine For Vials, Automatic Injectable Vial Filler and Rubber Stoppering Machine, Automatic Vial Filling and Bunging Machine, Automatic 12/8/6/4 Head Vial Filling Machine & Stoppering Machine.

- The machine has a facility of using PRIME function for all the peristaltic pumps together or individual peristaltic pumps also The process of filling is done by specially designed filling peristaltic pump which can serve the purpose of CIP & SIP Individual pumps can be adjusted & calibrated for the desired volume – by use of easy to operate PLC Oil based material can also be run easily without dripping because of specially designed peristaltic pump with the facility of suckback The each filling head can work independently & hence machine works continuously without sacrificing major production No change parts are required for different size of vials as well as different filling volume There is a very less product change over time due to very less usage of mechanical parts such as syringe set, Teflon seal, gear & chain etc Easy to operate PLC for any kind of volume adjustment or speed adjustment Synchronized filling system for smooth filling purpose Specially designed bung oriental bowl & discharge chute with in-built vibrator. The bung oriental bowl & chute are Teflon coated for use of wet bungs Bungs are hold in the specially designed vacuum bung hold disc & the same disc discharge the bung uniformly on the vial. The bung pressing roller presses the bungs uniformly The same Rubber bunging machine assembly can also be utilized for half stoppering For different heights of vials, the whole assembly can be moved upwards & downwards Alarm alerts through PLC for No Vial, Machine Stop & No Vial, No Bung Production counter is given with password protection for daily track report and planning for the same The faults can be detected on the PLC touch screen HMI and can be attended easily for the same The machine is supplied with isolated power supply to avoid adverse effect of electric supply The output speed can be appeared on HMI screen and adjust the same as per appropriate requirements Very less mechanical adjustment required due to the special design User friendly and very less maintenance required Nitrogen facility (Pre or Post) can be provided as an (OPTIONAL) Unique design of rolling conveyor Easy loading of vials to in-feed turntable - by loading tray

Other products from this brand

Ultrafiltration Membranes

Thickness Gauge

$163

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Recommended Products

Jar Filling Machine

Jar Filling Machine

Jar Filling Machine

Jar Filling Machine

Jar Filling Machine

Jar Filling Machine

Jar Filling Machine

Jar Filling Machine

Jar Filling Machine

Jar Filling Machine

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon