Ultrafiltration Membranes

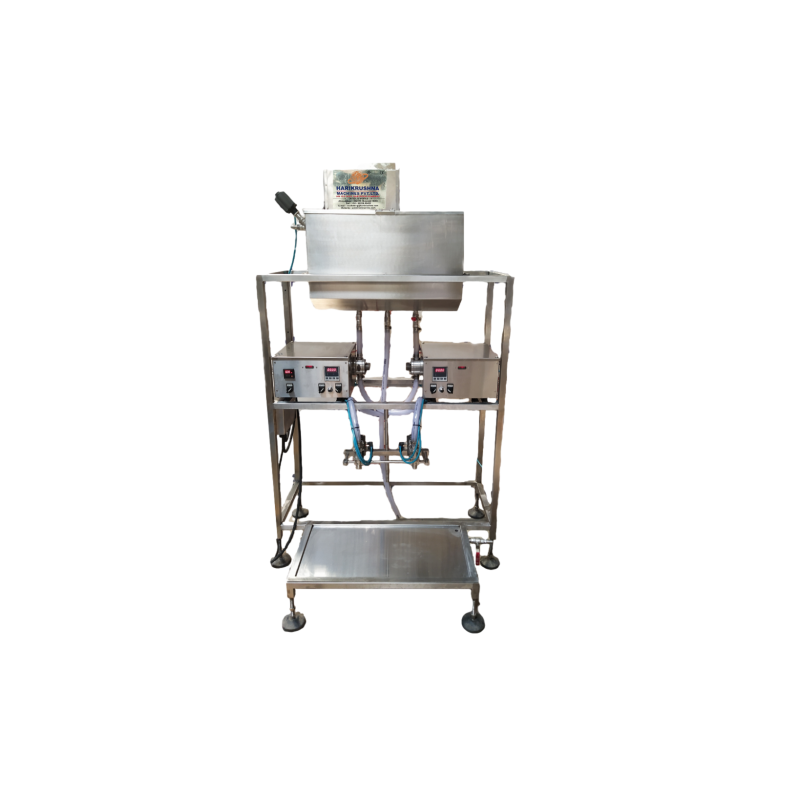

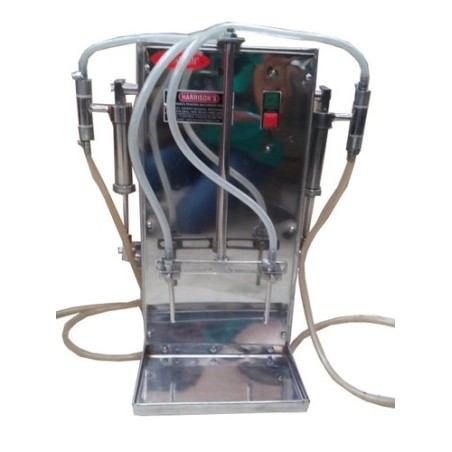

Semi Automatic Timer Filling Machine HMPL-STF-TT-2

Quantity

Reference ACFUR Category Jar Filling Machine

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Semi Automatic Timer Filling Machine HMPL-STF-TT-2

Reference ACFUR Category Jar Filling Machine

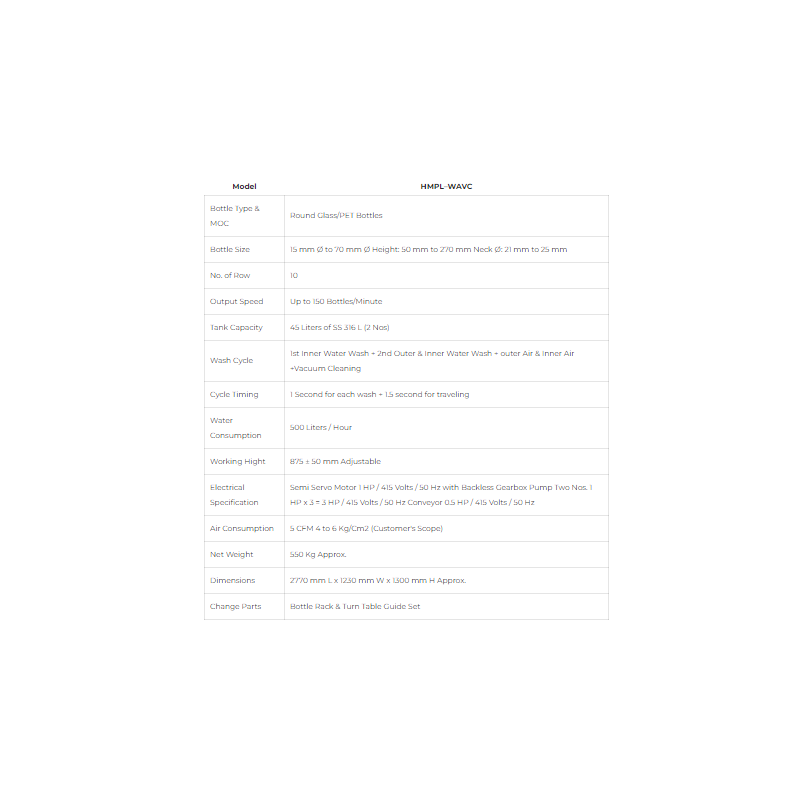

Specifications

| Model | HMPL-STF-TT-1 |

|---|---|

| Suitable for | 50 ml to 5000 ml |

| Net Weight | 150 Kg Approx. |

| Usage/Application | Industrial |

| Power Supply | Three Phase / 440 V AC / 50Hz |

| Air consumption | 4 to 6 Kg/Cm 5 CFM |

| Filling Capacity | 50 ml onward |

| Output / minute | 20 to 25 bottles (Water) (Depending upon volume viscosity of Liquid & manual loading unloading) |

| Pump Capacity | Depends on viscosity of product and volume. |

Key Features

- Prime with variable speed facility. Individual Prime facility for each Pump. Pump start with settable time in auto mode. Settable time facility to dispense different volume. Settable speed facility to dispense different viscosity product (important feature for foamy product). Adjustable filling nozzle with horizontal and vertical movement for different diameter and different Height products with adjustable product guide. Anti-shutoff valve to avoid dripping.

Product Details

Semi Automatic Timer Filling Machine Model HMPL-STF-TT-1 The Semi Automatic Timer Filling Machine consists of the main structure of SS, product holders, 100 liters tank with a stirrer, level controller, filling pump, filling nozzle, auto & manual mode, pedal switch & AC drive.The Machine is manufactured or developed accordance with GMP standards.The whole structure is made of SS 304 matt finish.The contact parts are made of SS 316 such as pump / nozzle / tank & valve.Rigid vibration free construction for trouble free performance.Use of food grade PVC breaded for the flow of liquid.The each filling head can work independently.Unique Bottle & Nozzle holding device.The storage tank with stirrer, level controller, auto inlet valve, over flow connection.The machine is supplied with easy to clean inbuilt storage tank.The drain valve below the filling tank for flushing purpose.Drain tray around the machine platform.Filling pump which is useful to suck the filling material from storage tank to nozzle end very quickly. More over this facility is useful to clean filling line as well as filling pump. The same function for individual pumps.

Other products from this brand

Ultrafiltration Membranes

Thickness Gauge

$163

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Recommended Products

Jar Filling Machine

Jar Filling Machine

Jar Filling Machine

Jar Filling Machine

Jar Filling Machine

Jar Filling Machine

Jar Filling Machine

Jar Filling Machine

Jar Filling Machine

Jar Filling Machine

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon