Ultrafiltration Membranes

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

- Genuine Products

- Global Shipping

- Secured Payments

Grate Cooler 1000 TDP

₹1

Quantity

Specifications

| Material | M.S |

|---|---|

| Capacity | Upto 1000 tpd |

| Shape | Granular or powder |

| Condition | New |

| Design Type | Customized |

| Automatic Grade | Automatic |

Key Features

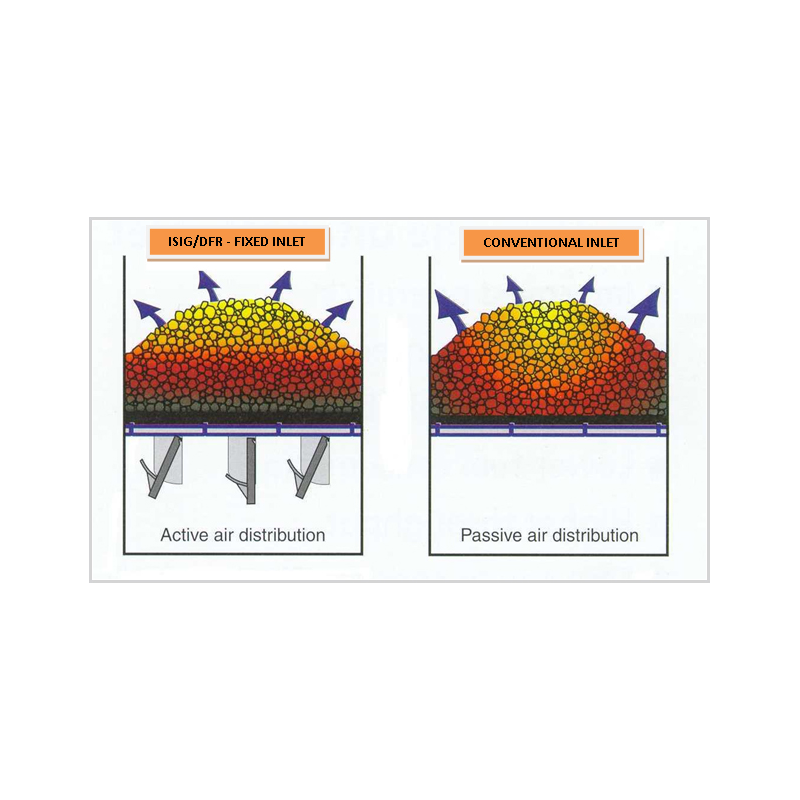

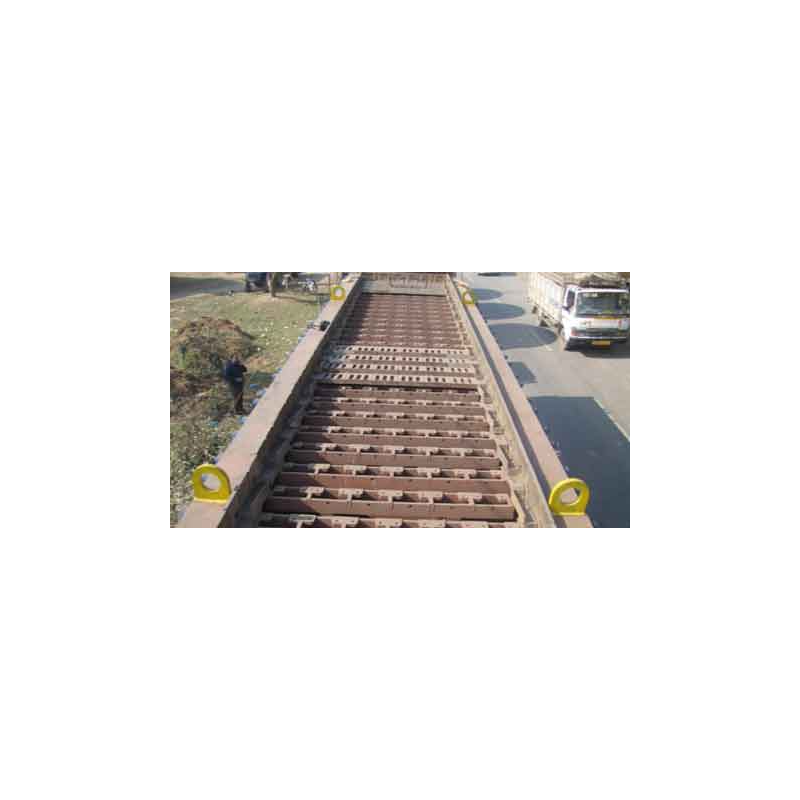

- This is an inclined arrangement of specially designed anti spillage Grate plates, arranged in downward steps formation. These Grate Rows do not move. The Castable cover is shaped in such a way to have spread of hot clinker on grate without void.

- The high depth hot clinker bed is formed which is supplied with a concentrated Air load underneath. This results in quick and high grade heat recovery from clinker. This heat is supplied in the form of Secondary and Tertiary Air flow to kiln and Calciner at optimum proportions.

Reference ABNXW Category Industrial Air Cooler

Product Details

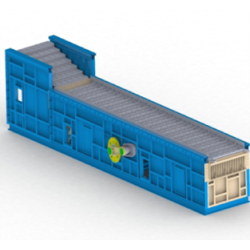

Industrial Clinker Cooler is extensively used to cool the clinker and extracted heat from hot clinker is supplied at secondary and tertiary air to kiln. Acknowledged for its optimum specific grate load, this ensures lower heat consumption. It is basically supplied in two independent entities inlet stationary inclined grate and reciprocating clinker grate cooler which are then joined together for achieving maximum recuperation of heat. Moreover, the cooler operates with no risk of "Snowman" formation as there are air blasters installed at front and side walls.HIGHLIGHTSSpecific Grate load:45 - 50 t/d m2Designed cooling air: 2.0 -2.2Nm3/kg ClinkerRequired cooling air: 1.7 -1.8 Nm3/kg ClinkerProvided with Inlet Stationary inclined Grate(ISIG) and Dynamic Flow regulator(DFR)Lower heat consumption/Kg Clinker due to High Secondary Air temperature which helps in intense burner flameHigh Tertiary Air causes good degree of Pre-calcination in Calciner and reduces fuel consumptionNo Internal Ducting/manual DampersUniform Distribution Of Air Through-out the with Inlet Stationary inclined Grate (ISIG) Zone ensured By Dynamic Flow Regulators (DFR)Air Blasters Installed At Front & Side Walls Eliminate Snowman FormationNo Clinker Fall Through

- As ISIG does the major heat recovery task, for balance Clinker cooling it is equipped with conventional Reciprocating Grate Cooler.

Other Products from this Brand

Ultrafiltration Membranes

Thickness Gauge

₹13,785

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Turbine Blower

Industrial Valves

₹548

Recommended Products

Industrial Air Cooler

Industrial Air Cooler

Industrial Air Cooler

Industrial Air Cooler

Industrial Air Cooler

Industrial Air Cooler

Industrial Air Cooler

Industrial Air Cooler

Industrial Air Cooler

Industrial Air Cooler

Industrial Air Cooler

Industrial Air Cooler