Ultrafiltration Membranes

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

- Genuine Products

- Global Shipping

- Secured Payments

Rotary Dryer Machine

Quantity

Specifications

| Application | Iron Ore Slag Pozzolana Gypsum Coal/Coke Clay Fly-ash Limestone |

|---|

Key Features

- Our enhanced flight design ensures better cascading action and avoids large clusters of material falling during flight and hence better heat transfer.

- Handle high feed moisture Volumetric filling is about 10-15% ensures better efficiency.

Reference ABOEL Category Dryers

Product Details

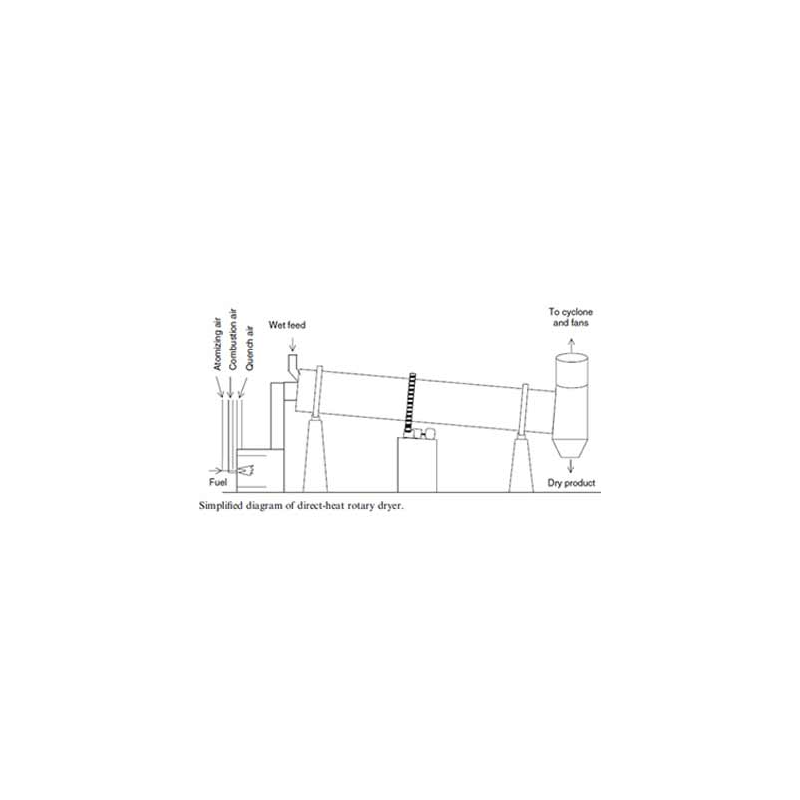

CPG provides two types of Dryers depending upon application. These are multistage & single stage Dryers. Dryer is used for drying materials with a certain humidity or granularity for grinding of ores, building materials, metallurgy and chemical industry. CPG offers Rotary Dryers for wide variety of applications like slag rotary dryer and building material rotary dryer depending upon moisture content. The Rotary Dryer is a continuously operated direct contact Dryer consisting of a slowly revolving cylindrical shell that is typically inclined to the horizontal a few degrees. The wet material is dried with the help of hot gases that may be generated in an external furnace or by any available source. Wet feed is introduced into the upper end of the Dryer and the feed progresses through it by virtue of rotation, head effect, and slope of the shell and dried product with drawn at the lower end. The direction of gas flow through the cylinder is dictated mainly by the properties of the processed material which may be Co-Current or Counter-Current.

- Depending upon material to be processed, option for co-current and counter current flow is available.

Other Products from this Brand

Ultrafiltration Membranes

Thickness Gauge

₹17,843

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Turbine Blower

Industrial Valves

₹700

Recommended Products

Dryers

Dryers

Dryers

Dryers

Dryers

Dryers