Ultrafiltration Membranes

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

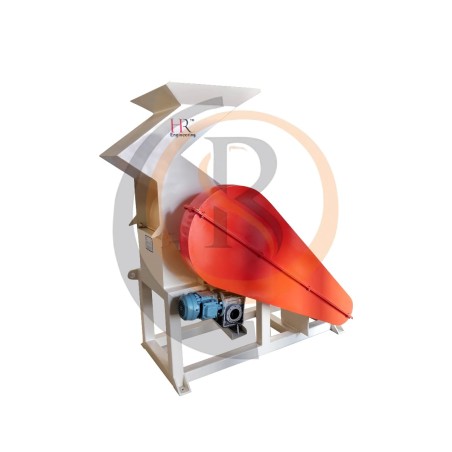

Roller Crusher

Reference AAGIO Category Crushers

Specifications

| Power | depend upon production of material |

|---|---|

| Production Capacity | 0.5 10 Ton/Hr. (According to Requirement of client) |

| Out Put Size | 10-100 Mesh (D97%) Passing |

Key Features

- We design plant according to requirement of consumer.

- High throughput capacity

- A variety of roll tooth profiles available

Product Details

A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. The gap between the rolls is set to the size of product desired, with the realization that the largest feed particle can only be 4 times the gap dimension. The particles are drawn into the gap between the rolls by their rotating motion and a friction angle formed between the rolls and the particle, called the nip angle. The two rolls force the particle between their rotating surface into the ever smaller gap area, and it fractures from the compressive forces presented by the rotating rolls. Some major advantages of roll crushers are they give a very fine product size distribution and they produce very little dust or fines. Rolls crushers are effectively used in minerals crushing. Usually, these crushers will have teeth or Smooth forms on the face of the roll. Roll crushers used for minerals and metal ores have smooth faced rolls.

- Adjustable for change in product sizing

- Automatic tramp relief

- Low cost per ton operation

Other products from this brand

Ultrafiltration Membranes

Thickness Gauge

$163

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Recommended Products

Crushers

Crushers

Crushers

Crushers

Crushers

Crushers

Crushers

Crushers

Crushers

Crushers

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon