Rotary Kiln

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

- Genuine Products

- Global Shipping

- Secured Payments

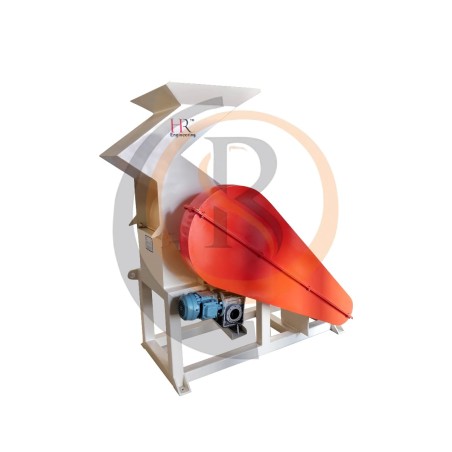

Jaw Crushers HSC590

Quantity

Specifications

| Type | Equipment |

|---|---|

| Technology | Sampling preparation and analysis Sampling preparation and analysis - Mining |

| Industry | Mining Port and terminals More |

| Product family | Crushing |

Key Features

- the HSC590 will save time for your operators and your processes. Its jaw can be quickly and easily locked and unlocked using a wide non-slip handle to speed cleaning and inspection of the crushing chamber, and to make cleaning hassle free

- A range of safety mechanisms protect your operators from harm. A safety switch and brake motor ensure immediate shut-down if the jaw crusher is incorrectly opened or switched on

Product Details

With the ability to crush material with a feed size of up to 90 mm, our HSC590 Jaw Crusher is a real workhorse. It crushes to a final fineness of < 4mm and with a gap width of 0-30 mm. It can be operated in automatic, standalone, and standalone with magazine, linear automation, and robot automation modes, introducing newfound flexibility to your processes and setting.With the ability to crush material with a feed size of up to 90 mm, our HSC590 Jaw Crusher is a real workhorse. It crushes to a final fineness of < 4mm and with a gap width of 0-30 mm. It can be operated in automatic, standalone, and standalone with magazine, linear automation, and robot automation modes, introducing newfound flexibility to your processes and setting. Our HSC590 is known for its quality crushing performance and is suited for use with a raw meal, clinker, cement, slag, ores, oxidic material, and ferroalloys, in preparation for further grinding

- The fixed crushing arm can be easily and safely removed for cleaning and jaw replacement. Additionally, our HSC590 comes fitted with a no-rebound hopper. The feed funnels design prevents the operator from reaching into the funnel, and a hinged opening allows for fast and easy cleaning of the grinding chamber.

Other Products from this Brand

Feeder

Plastic Granules Machine

Pipeline Accessories

Customised Products

Filter Bags

Filter Bags

Conveyors

Conveyors

Milling Machines

Digital Analyzers

Recommended Products

Crushers

Crushers

Crushers

Crushers

Crushers

Crushers

Crushers

Crushers

Crushers

Crushers

Crushers

Crushers