Rotary Kiln

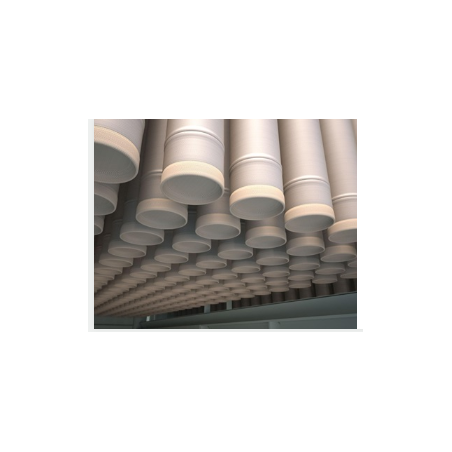

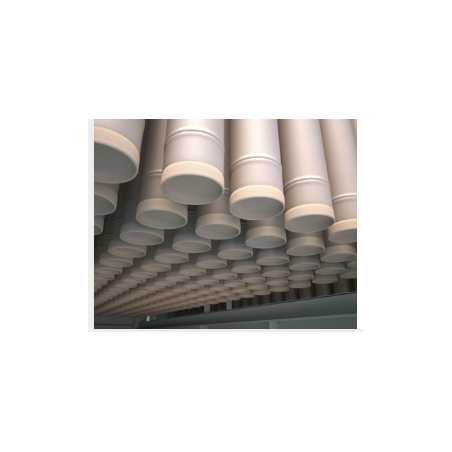

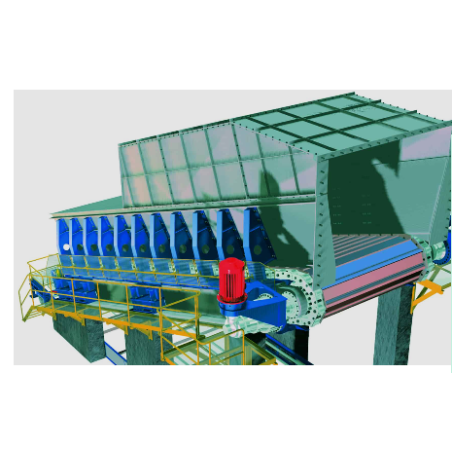

Airslide Gravity Conveyors

Quantity

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Specifications

| Type | Equipment |

|---|---|

| Usage/Application | Minimise installation site prep and field work Reduce power requirements Reduce transfer points Reduce operating costs |

| Technology | Conveying Material handling |

| Industry | Cement Mining More |

| Product family | Pneumatic dry bulk handling systems |

| Benefits | Very low maintenance with no moving parts Completely enclosed dust-free system Extremely low energy costs Maximum flexibility thanks to extensive accessory options Dense phase conveying for high throughput |

Key Features

- Thanks to the low conveying speed and simple construction, Airslide gravity systems convey even high volumes of materials gently, without segregation and with very low wear. This gives you a long equipment life with virtually no maintenance.

- Our Airslide Conveyors are built with flexibility in mind, so weve designed a variety of attachments and accessories to enable a broad range of uses. Branch points, distributing systems, ejection flaps, or shut-off units and regulating units enable a large number of individual conveying section variations. Adaptations can also be made for high-wear or high-temperature materials up to 400°C.

Product Details

Airslide Gravity Conveyors Low-maintenance Airslide fluidized conveying systems take advantage of natural forces to transport fluidised bulk materials at rates of 2000 m3/h and more Working at speeds of 2000 m3/h and more, these enclosed fluidized conveying systems are dust-free, low wear and low maintenance, yet highly efficient. They can be used across the plant, in applications such as conveying bulk material from silos to vehicle or ship loading facilities, receiving material from bucket elevators for further distribution to silo chambers, or where multiple material flows meet for transport on to a common station.

Other products from this brand

Feeder

Plastic Granules Machine

Pipeline Accessories

Customised Products

Filter Bags

Filter Bags

Conveyors

Milling Machines

Recommended Products

Conveyors

Conveyors

Conveyors

Conveyors

Conveyors

Conveyors

Conveyors

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon