Ultrafiltration Membranes

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

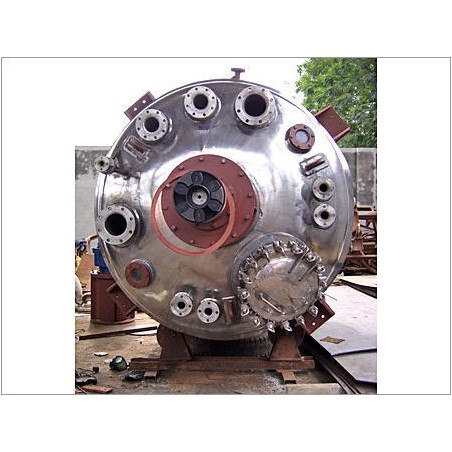

Reaction Vessels

Reference AAGIN Category Chemical Reactors

Specifications

| Operation | Atmosphere or vacuum |

|---|---|

| Capacity | 100 Liters to 50| 000 Liters |

| MOC | S S-304 /S S-316 /M.S/Special Alloy |

| Coiling | S S-304/S S-316/M.S/Special Alloy |

| Agitation | Through Agitator |

Key Features

- Excellent finishing

- Superb quality

- Heat & chemical resistance

- Easy to install & maintain

Product Details

Reaction Vessels are used in carrying out a wide variety of chemical reactions including condensation, polymerization, esterification , hydrogenation etc. at pressures (Up to 30 Kg. / cm) and at temperatures ranging -20C to +250C. Reaction needing simultaneous fractional distillation and azeotropic distillation can also be conducted very efficiently using these chemical reaction vessels.Material of ConstructionsVarious materials of construction, such as MS, SS304, SS 316, SS 316L, SS410, Rubber Lined etc., can be offered as per requirement. Capacities:We offer high quality reaction vessel in different capacities ranging from 50 liters to 35,000 liters.Types Of AgitatorThese vessels can be provided with different types of agitators such as anchor type, propeller type, paddle type, pitched blade turbine type of high-speed homogenizer Sealing Of Shaft : Reactors are provided with Gland box or Mechanical seals for shaft sealing arrangement of the shaft with the vessel.Stuffing Box : Stuffing boxes accomplish sealing by the radial expash alimar on of a soft, deformable material . Mechanical Seal: Mechanical seals are designed to prevent leakage between a rotating shaft and its housing under conditions of extreme pressure, shaft speed and temperature. Mechanical seals can be single acting or double acting. Single (acting) mechanical seals have one sealing gap. Mechanical seals tend to leak a vapor from the high pressure side to the low pressure side. This fluid lubricates the seal faces and absorbs the heat generated from the associated friction, which crosses the seal faces as a liquid and vaporizes into the atmosphere. So, it's common practice to use a single mechanical seal if the product poses little to no risk to the environment.Double Mechanical SealLimped Coil VesselFoodPharmaceuticalsChemicalsPigmentsOrganic ChemicalsInorganic Chemicals

- Easy to move from one place to another

Other products from this brand

Ultrafiltration Membranes

Thickness Gauge

$163

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Recommended Products

Chemical Reactors

Chemical Reactors

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon