Ultrafiltration Membranes

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

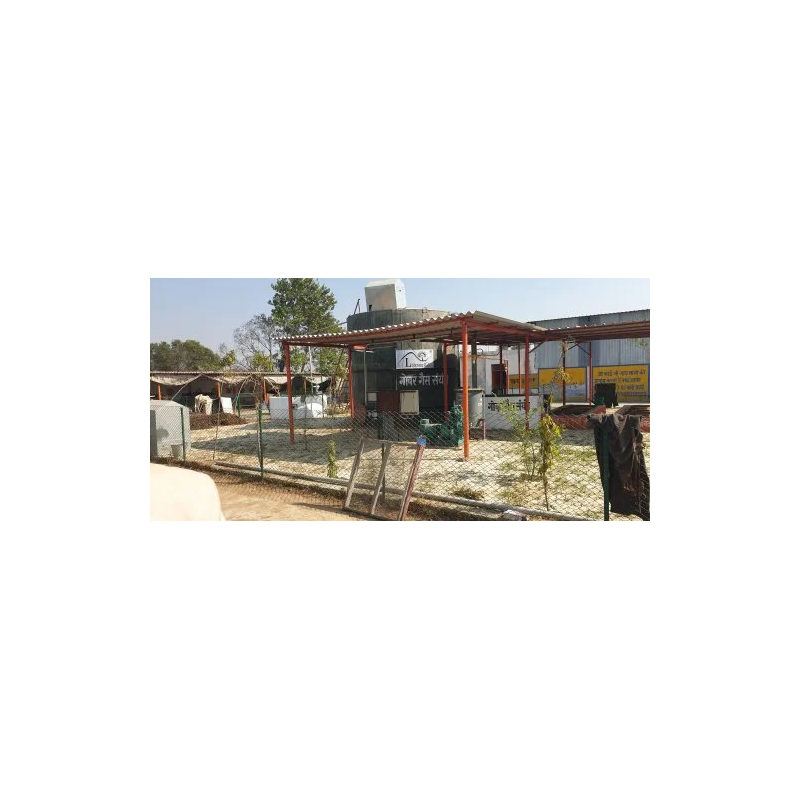

Biogas Digester Capacity 20Kg To 1000 Tons

Reference ABZUC Category Biogas Digester

Specifications

| Material | MS/ RCC/ GFS/ Flexi |

|---|---|

| Voltage | Single Phase |

| Capacity | 1 cubic meter to 25000 + cubic meter |

| Usage | Industrial |

| Frequency | 50 - 60 Hz |

| Finish | Color Coated |

| Usage/Application | Industrial and Agricultural |

| Country of Origin | India |

| Temperature | 35 - 40 Degree C |

| Frame Material | Mild Steel |

| Waste Input | 20 kg to 1000 tons |

| Plant Design | Automated Heating System |

| Plant Size | Assorted |

| Heater Material | Copper |

Key Features

- High performance

Product Details

Biogas Digester Capacity 20 Kg To 1000 Tons, A biogas digestor uses natural anaerobic decomposition of organic matter under controlled conditions. The digestor is usually a large, sealed container for the organic matter eg manure from livestock or poultry, green waste from agriculture, sewage or food waste.The digester uses CSTR Technology (Constant Stirring Type Reactor)The Digester (Fixed dome/ Floating dome) is made from Mild Steel (TATA, JINDAL, SAIL, BHUSHAN)/ RCC/ Glass Fused Tank. Additional structure is given to increase the strength and life of digester.3.5 mm FRP coating inside the digester and 1.5 mm FRP coating is done outside the digester to have thermal insulation and long life.PUF coating can also be done in extreme temperature variance areas.HRT is 30 to 35 days i.e. the material feed today comes out through overflow after 30-35 days with average temperature of 35 400 C throughout the year.8% - 10% solid content is maintained inside the digester for maximum output.Internal heating system (Heat recovered from Genset) is also used to maintain digester temperature if needed.Mixing Pattern: Mixers should ensure the Precise Maintenance of Different Digestion Zones (Hydrolysis, Acidogenesis, Acetogenesis and Methanogenesis) inside the DigesterThe digester uses CSTR Technology (Constant Stirring Type Reactor)The Digester (Fixed dome/ Floating dome) is made from Mild Steel (TATA, JINDAL, SAIL, BHUSHAN)/ RCC/ Glass Fused Tank. Additional structure is given to increase the strength and life of digester.3.5 mm FRP coating inside the digester and 1.5 mm FRP coating is done outside the digester to have thermal insulation and long life.PUF coating can also be done in extreme temperature variance areas.HRT is 30 to 35 days i.e. the material feed today comes out through overflow after 30-35 days with average temperature of 35 400C throughout the year.8% - 10% solid content is maintained inside the digester for maximum output.Internal heating system (Heat recovered from Genset) is also used to maintain digester temperature if needed.Mixing Pattern: Mixers should ensure the Precise Maintenance of Different Digestion Zones (Hydrolysis, Acidogenesis, Acetogenesis and Methanogenesis) inside the Digester.

Other products from this brand

Ultrafiltration Membranes

Thickness Gauge

$163

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Recommended Products

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon