Ultrafiltration Membranes

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

- Genuine Products

- Global Shipping

- Secured Payments

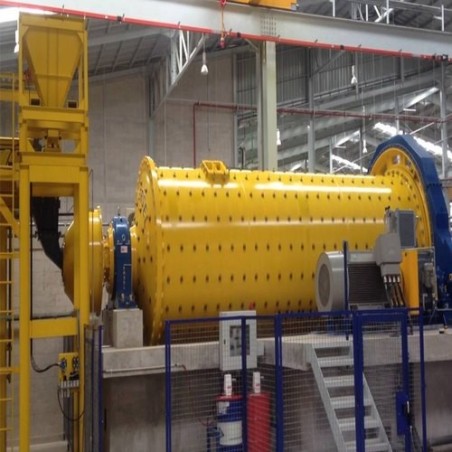

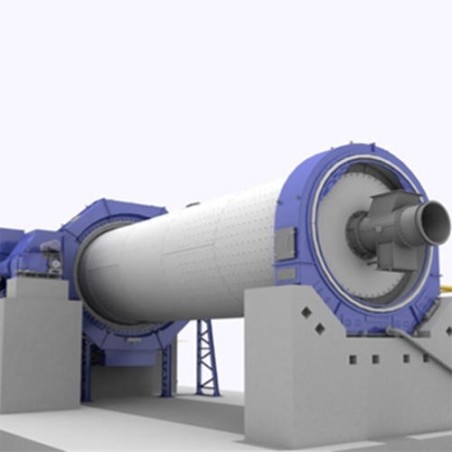

Ball Mill Girth Gear

Quantity

Specifications

| Brand | CPG-GR |

|---|---|

| Automation Grade | Automatic |

| Condition | New |

| Customisation | Customised |

Key Features

- Gear rim is casted and received in two halves Non destructive testing is performed to ensure zero defects

- Machining of gear in multiple steps to ensure best finish and accuracy Final quality inspection to ensure CPG quality

Reference ABOFU Category Ball Mills

Product Details

Girth Gear Ball Mill This girth gear is precisely designed using excel quality raw material as per DIN 3962 accuracy class VIII. Cast rims for gear are procured by the most trusted and reliable vendors in this domain. Our quality experts check the product at each and every stage of manufacturing process according to the set international industrial standards. Our product is highly appreciated amongst customers for its superior design, dimensional accuracy, excellent strength and easy installation. This girth gear is widely demanded in different industries to be installed in different machines such as Rotary Kilns, Rotary Dryers and Ball Mills. It is available in different specifications according to the requirements of the customers. Furthermore, to meet the variegated demands of the clients, our company provides this product at pocket friendly priceOUR ADVANTAGEGirth gear manufacturing by double stress relieving processBasic tooth profile as per DIN 3972 IIAccuracy grade as per DIN 3968 AA.We ensure quality through NDT UT MPI DPT.Gear Tooth profile Inspection By Chordal Thickness measurement at various Chordal Addendum and Base Tangent Length at various position radially and axiallyTooth Profile run out Measurement over pin.Pitch measurement by pitch measuring Instrument at various position radially and axially.Surface Finish measurement by German digital Surface finish measuring instrument.

Other Products from this Brand

Ultrafiltration Membranes

Thickness Gauge

₹17,843

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Turbine Blower

Industrial Valves

₹700

Recommended Products

Ball Mills

Ball Mills

Ball Mills

Ball Mills

Ball Mills

Ball Mills

Ball Mills

Ball Mills

Ball Mills

Ball Mills

Ball Mills

Ball Mills