Ultrafiltration Membranes

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

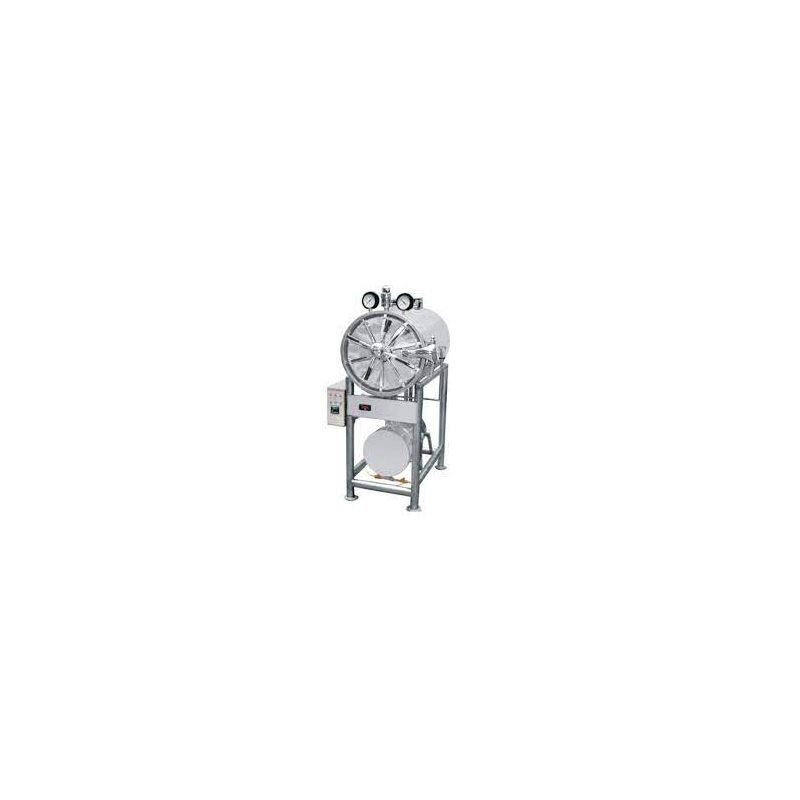

Horizontal Autoclave 260 V

Reference ABPLH Category Autoclave

Specifications

| Type | Pressure Steam Sterilization |

|---|---|

| Material | Stainless Steel |

| Voltage | 260 V |

| Power Source | Electric |

| Frequency | 50 Hz |

| Model No | HA-002 |

| Automation Grade | Semi Automatic |

| Working Temperature | 145 deg C |

Key Features

- Long functional life.

- Hassle-free operations.

- Corrosion & abrasion resistance.

- Easy installation.

Product Details

The ball mill is a key piece of equipment to grind the crushed materials, and the ball mill is widely used in powder-making production lines including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc, and the ball mill can grind various ores and other materials with dry type and wet type. Ball Mill consists of a cylindrical shell mounted on a sturdy Mild Steel Frame. The Ball Mill Shell is designed to withstand the rotational load of the mill charged with the grinding medium and the material to be processed. Openings are provided through which the grinding medium and the material to be processed are loaded and rotating on a horizontal axis discharged. This is driven by a motor coupled to a helical/reduction Gear box with a Gear and pinion arrangement. The Heavy Duty ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the opening feed mouth. There are different specifications of steel balls/ceramic balls in the chamber. The centrifugal force caused by the rotation of the barrel brings the balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished. Working RPM 30-40 rpm.

- Sturdy construction.

- Facilitates easy loading and unloading of material.

Other products from this brand

Ultrafiltration Membranes

Thickness Gauge

$163

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Recommended Products

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon