Ultrafiltration Membranes

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Air Classifying Mill

Reference AAGHZ Category Air Classifiers

Specifications

| Country of Origin | India |

|---|---|

| Warranty | As per Manufacturer |

Key Features

- Grinding and Classifying in one machine

- Cool and smooth grinding

- Steep particle size distribution

- Sharp Classifier cut point, instantly adjustable.

Product Details

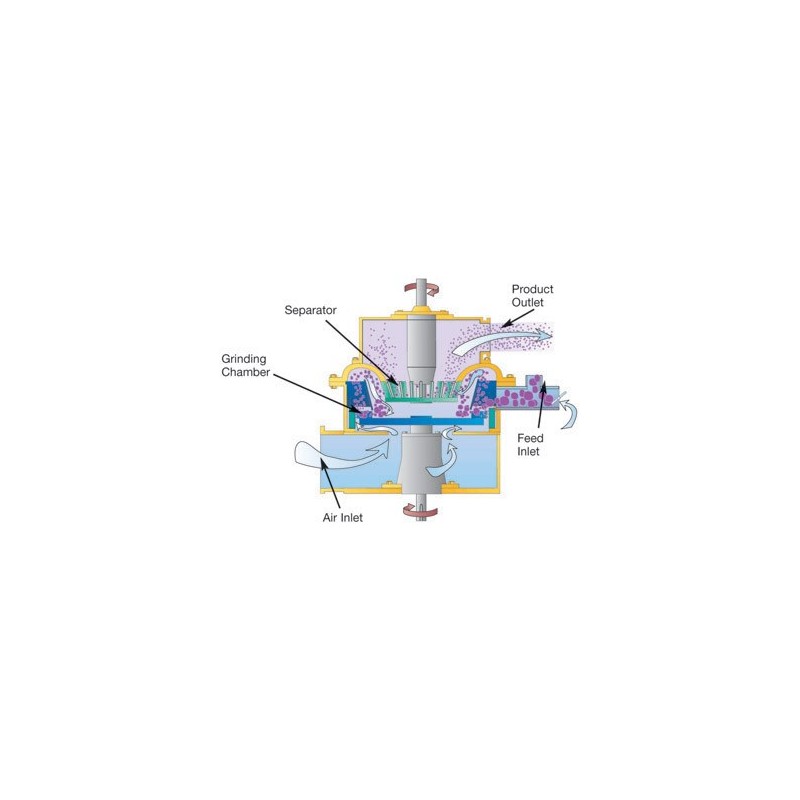

AIR.CLASSIFYING.MILL(ACM):Ultrafine Air Classifying Mills are used for size reduction of various products to microfine particle sizes. The system incorporates integral classifier where the fine particles of desired size are segregated and the over size particles back to the grinding chamber and re-grinded until the desired particle size is obtained. Air Classifying Mill is very compact and efficient, having sharp classifier cut points which are instantly adjustable. The system incorporates grinding and classification in one single compact space saving design.operating. PRINCIPLE:The material to be ground is conveyed from a hopper by screw feeder or pneumatically fed through Rotary Air Lock Feeder to the grinding chamber of the Air Classifying Mill (ACM). The pins/bars of the rotor break the particles of the material. These particles are entrained by an air stream which enters below the pin rotor and are carried up between the inner wall and the shroud ring with baffles which decrease the air swirl. These particle then enter the classifying section where the fine material is carried out with the air through the classifier rotor to the outlet, the course material is thrown against the shroud rind and carried down to the pin rotor for further reduction. After leaving the micronized air mixed with fine particles enter the bag filter where the fine particles are separated and the clean air is discharged to the atmosphere.

- Easy cleaning and maintenance.

- Low specific energy requirement

- Compact space saving design.

Other products from this brand

Ultrafiltration Membranes

Thickness Gauge

$163

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Recommended Products

Air Classifiers

Air Classifiers

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon