$0.88

($0.88 per kg)

Tax included

×

Product Enquiry

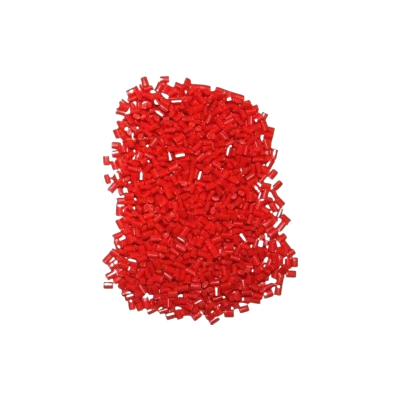

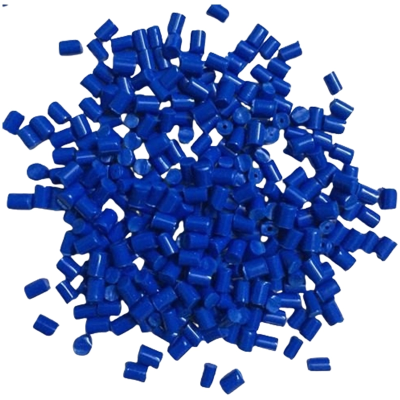

Acrylonitrile Butadiene Styrene FR Granule

Comments (0)

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent