Rotary Kiln

Krebs Millmax-e Slurry Pump

Quantity

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Krebs Millmax-e Slurry Pump

Specifications

| Type | Equipment |

|---|---|

| Technology | Pumping |

| Industry | Mining Power utilities More |

| Product family | Slurry Pumps |

Key Features

- Our millMAX-e hydraulically advanced impeller is part of what makes our slurry pump very efficient. Tight clearances between the impeller and casing limit recirculation and significantly increase efficiency. The millMAX-e slurry pump can handle applications requiring high speed and power

- Decreased total weight of the wet end reduces capital cost. At the same time, the hydraulically advanced impeller and overall efficient design delivers a maintenance-friendly slurry pump that will often allow you to downsize the drive motor, further minimising your cost while maximising your efficiency

Product Details

Our centrifugal millMAX-e slurry pump design increases wear life and provide higher efficiency to your plant processing applications.Like all the pumps in the KREBS family, the millMAX-e Pump includes the patented suction side sealing system. This technology sets us apart from other pump manufacturers because it reduces wear by maintaining suction side clearances within the pump. The controlled clearances reduce internal recirculation and eliminate the grinding between the impeller and suction side. The result allows users to maintain a constant flow, pressure, and efficiency as the pump wears, without having to speed up the pump. This extends the life of all wet end parts and reduces power consumption.

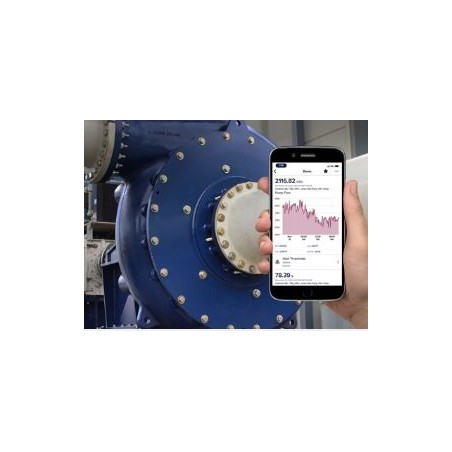

- With the combination of our SiteConnect™ app and KREBS® Smart Pumps, you now have access to real-time information about your pumps on any phone or mobile device. Get instant alerts about operational deviations so that you know about potential problems before they occur. With better information about current operation, historical data, trends and advanced calculations, one simple app gives you a snapshot of the overall health of your entire plant

- The millMAX-e has an optimised unlined wet end design to allow for easy maintenance, minimised space requirements, and low replacement costs

- To stop recirculation, pumps without a wear ring must adjust their impeller and suction liner close together. This can be effective when pumping fluids with no solids; with slurries, however, the solids become caught between the rotating impeller and static suction liner, and are crushed. Grinding these solids consumes power and wears out the impeller and liner. The millMAX wear ring stops stop recirculation, and allows for a large gap between the impeller and suction liner – eliminating solids grinding.

Other products from this brand

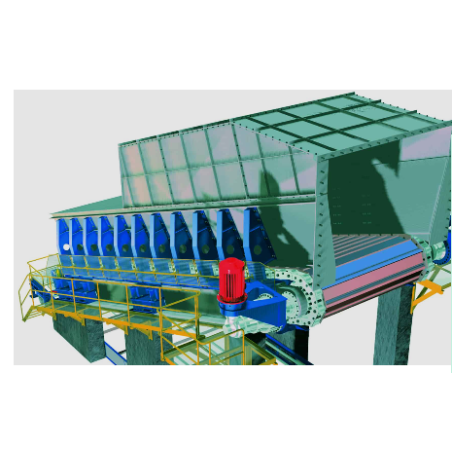

Feeder

Plastic Granules Machine

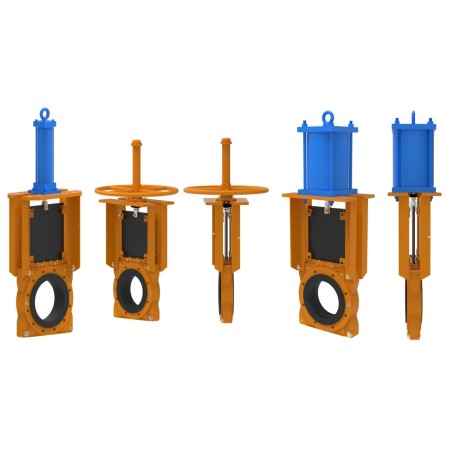

Pipeline Accessories

Customised Products

Filter Bags

Filter Bags

Conveyors

Conveyors

Recommended Products

Slurry Pumps

Slurry Pumps

Slurry Pumps

Slurry Pumps

Slurry Pumps

Slurry Pumps

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon