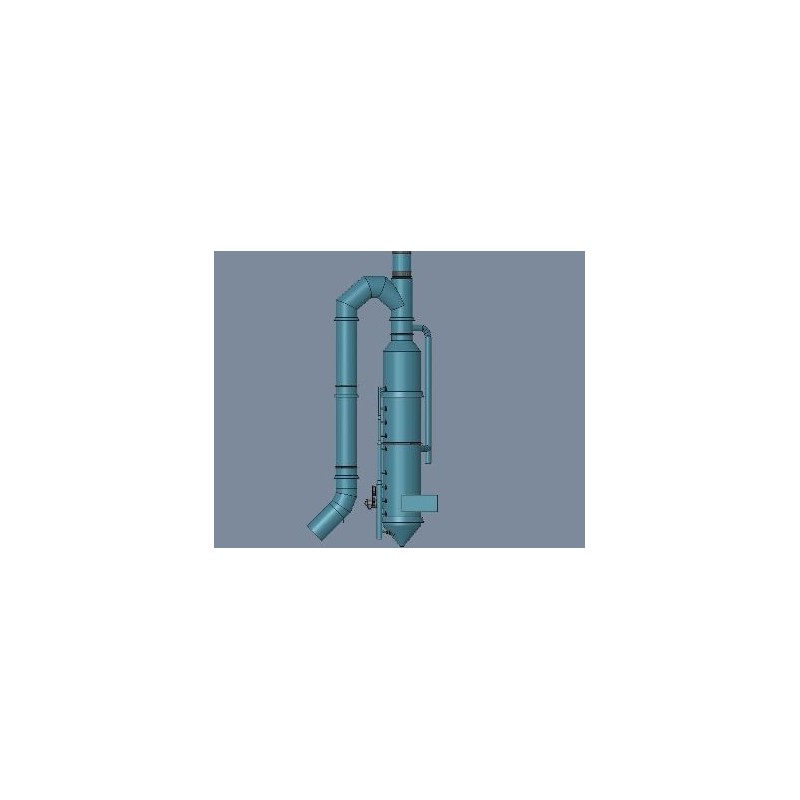

Rotary Kiln

Vertical Incinerator

Quantity

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

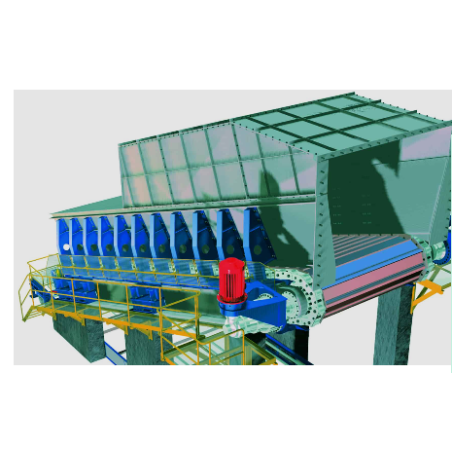

Vertical Incinerator

Specifications

| Type | Equipment |

|---|---|

| Technology | Pyromet |

| Industry | Mining |

| Product family | Stationary Incinerators |

Key Features

- Tangentially induced cyclonic inlet opening for the kiln exhaust gases, which effects both mixing of the injected ambient air and collection/drop-out of oversized carbonaceous particulate matter

- Vertical combustion air header pipe with injection nozzles for uniformly injecting ambient air along the height of the incinerator to effect mixing with the tangentially induced kiln exhaust gases and subsequent oxidation of remaining gaseous and solid fuels

Product Details

Our durable, high-quality Vertical Incinerator solutions are designed to optimize your calcination processes. By recycling rotary kiln exhaust gases, our Vertical Incinerators are able to cut energy costs and harmful emissions, while maximizing steam production.Vertical Incinerator solutions trap excess heat before it can be lost as exhaust. That heat is then put back into the machine. In this process, Ambient air is tangentially injected along the height of the vertical incinerator, mixing with the tangentially injected rotary kiln exhaust gases. The oxygen in the air oxidizes carbon monoxide, unburnt hydrocarbons and the carbon in the solid particulate matter in the kiln exhaust gases, producing additional energy for use in a downstream Waste Heat Boiler. And, as an added bonus, it reduces CO and hydrocarbon emissions

- Bottom collection / discharge dropout cone for oversized unburnt solids, which are returned as feed to the rotary kiln

- A two-component insulated refractory lining for protection of the shell and retainment of heat for increased production of steam

Other products from this brand

Feeder

Plastic Granules Machine

Pipeline Accessories

Customised Products

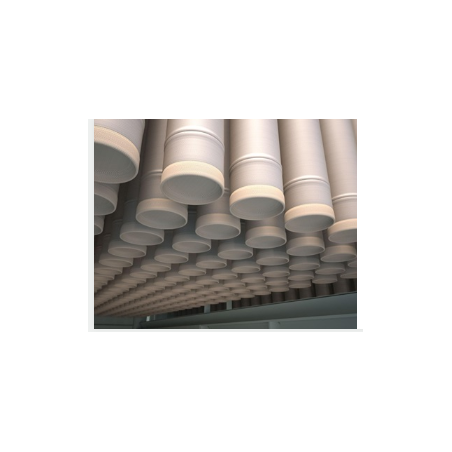

Filter Bags

Filter Bags

Conveyors

Conveyors

Recommended Products

Sanitary Napkin Incinerator

Sanitary Napkin Incinerator

Sanitary Napkin Incinerator

Sanitary Napkin Incinerator

Sanitary Napkin Incinerator

Sanitary Napkin Incinerator

Sanitary Napkin Incinerator

Sanitary Napkin Incinerator

Sanitary Napkin Incinerator

Sanitary Napkin Incinerator

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon