Rotary Kiln

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

- Genuine Products

- Global Shipping

- Secured Payments

Pyroprocessing Shaft Dryer

Quantity

Specifications

| Type | Equipment |

|---|---|

| Technology | Pyromet |

| Industry | Mining |

| Product family | Stationary dryers |

Key Features

- Preheated air (e.g. 300 °C) reaches the upper as well as the lower part by means of a drying air fan. In the upper section, the hot gas enters the chamber and flows through a bundle of pipes from top to bottom. The pipes warm up and contribute to the drying process. To reach the required heat, the drying air is heated to a constant and controlled drying temperature by using an air heater

Product Details

Developed in close cooperation with the refractory industry, the Pyroprocessing Shaft Dryer delivers exactly the performance you need for efficient and sustainable operations. With high thermal efficiency and low maintenance, this pellet dryer is a state-of-the-art solution for drying pellets and briquettes.The needs of the refractory industry are at the heart of the design of the Pyroprocessing Shaft Dryer, which offers unprecedented efficiency for drying material pellets such as aluminum oxide or spinel.This unique pellet dryer enables you to reduce the moisture content of pellets or briquettes to a level acceptable for furnace charging. Efficiency is gained through the highly effective heat exchange and the generation of only a small amount of fine dust. The latter not only improves efficiency but also ensures maintenance and wear stay low

- In the lower section, a cross construction and an arrangement of gas entry and exit cones ensure the distribution of the hot gas, which passes through the material in counter flow. The dried material is discharged through a cone into a tube, which empties into a vibrating feeder

Other Products from this Brand

Feeder

Plastic Granules Machine

Pipeline Accessories

Customised Products

Filter Bags

Filter Bags

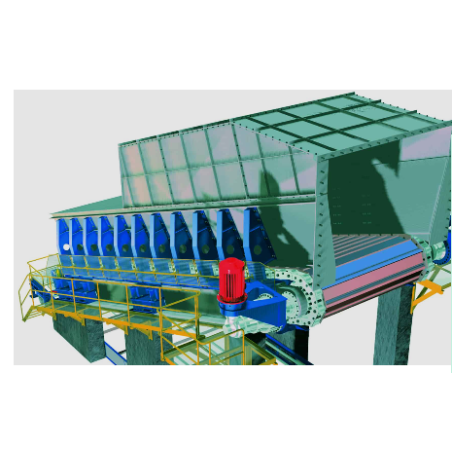

Conveyors

Conveyors

Milling Machines

Digital Analyzers