Rotary Kiln

Cyclone Preheater

Quantity

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

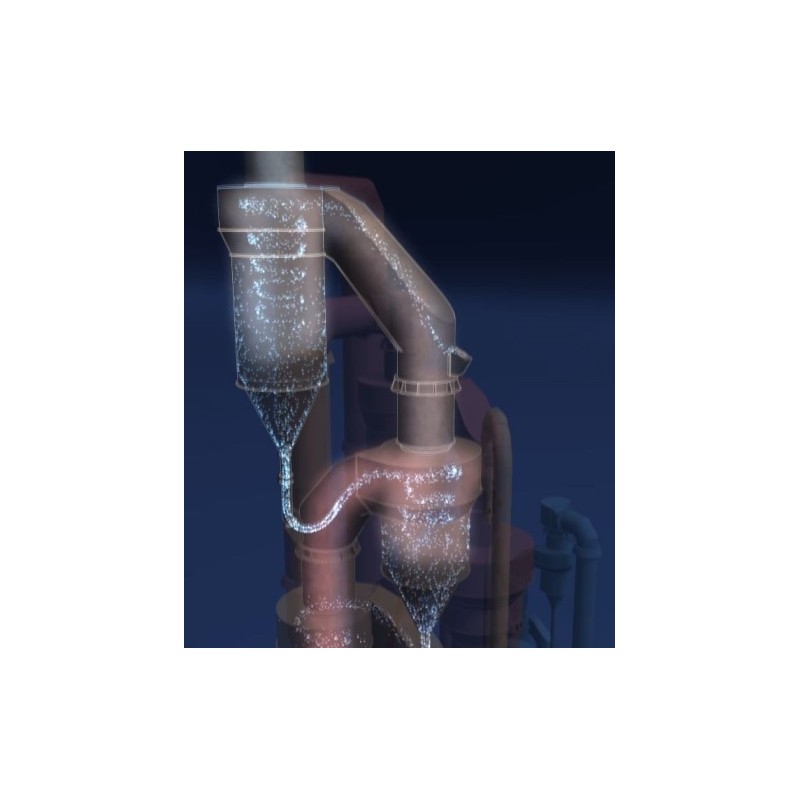

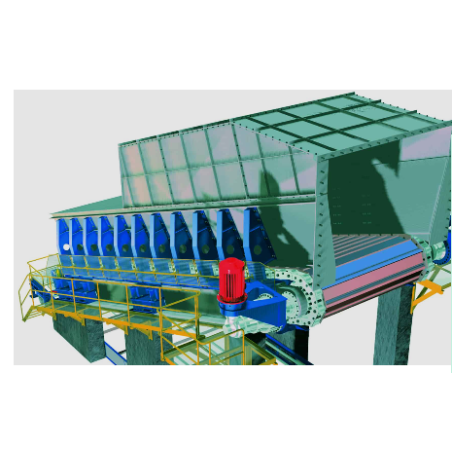

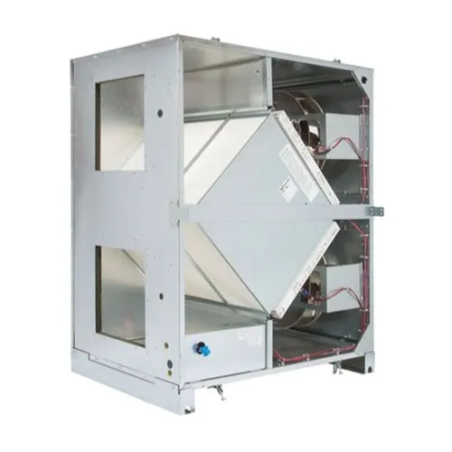

Cyclone Preheater

Specifications

| Type | Equipment |

|---|---|

| Technology | Pyromet |

| Industry | Mining Aggregates |

| Product family | Stationary preheaters and coolers |

Key Features

- These feed points are separated by an expanded riser duct that forms a NOx reducing zone. That is, the calcining chamber is built (at least partially) into the kiln riser. All of the calciner fuel is introduced to the kiln riser duct with less oxygen than required for complete combustion, thereby forming a reducing atmosphere

- High energy costs have a way of eating into your profits. By optimising both fuel and energy consumption, our Cyclone Preheaters empower your business to spend less, and net more

Product Details

Heating raw material to calcination temperatures has traditionally demanded a complex, high-energy, fuel-intensive process. Our Cyclone Preheaters change all of that. Their unique design simplifies calcination, while also allowing for better emission control and fuel efficiency, for a cost-effective solution thats also easy to use.The raw meal is introduced at the inlet gas duct to the Stage I (top) cyclones. It is subsequently preheated by hot, countercurrent gas flow as it is continuously collected and passed down the other cyclone stages in the preheater to the calciner. Fuel is burned in the calciner to achieve 92-95% of the total material calcination before collection in the bottom cyclone and entrance into the kiln

- Reduce operational expenses by relying on course, alternative fuels. Integrate our Cyclone Preheater with our safe, simple HOTDISC combustion device for cost-saving fuel flexibility

- Reduce your operations negative environmental impact; our Cyclone Preheaters offer an effective solution, with low NOx emissions with only one firing location, one meal split and one tertiary air stream entering the calciner

Other products from this brand

Feeder

Plastic Granules Machine

Pipeline Accessories

Customised Products

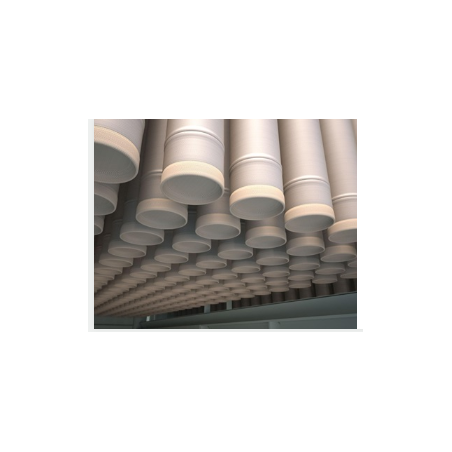

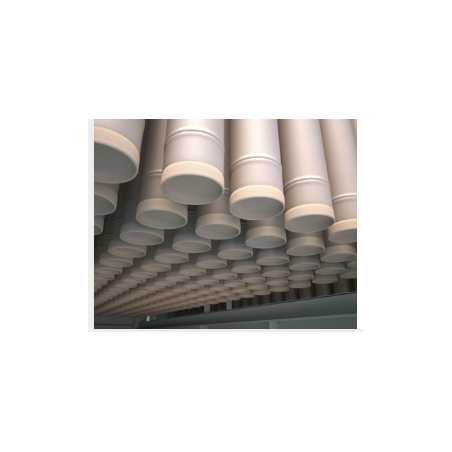

Filter Bags

Filter Bags

Conveyors

Conveyors

Recommended Products

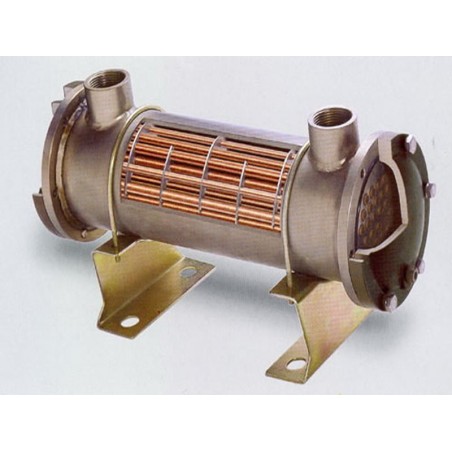

Heat Exchangers

Heat Exchangers

Heat Exchangers

Heat Exchangers

Heat Exchangers

Heat Exchangers

Heat Exchangers

Heat Exchangers

Heat Exchangers

Heat Exchangers

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon