Rotary Kiln

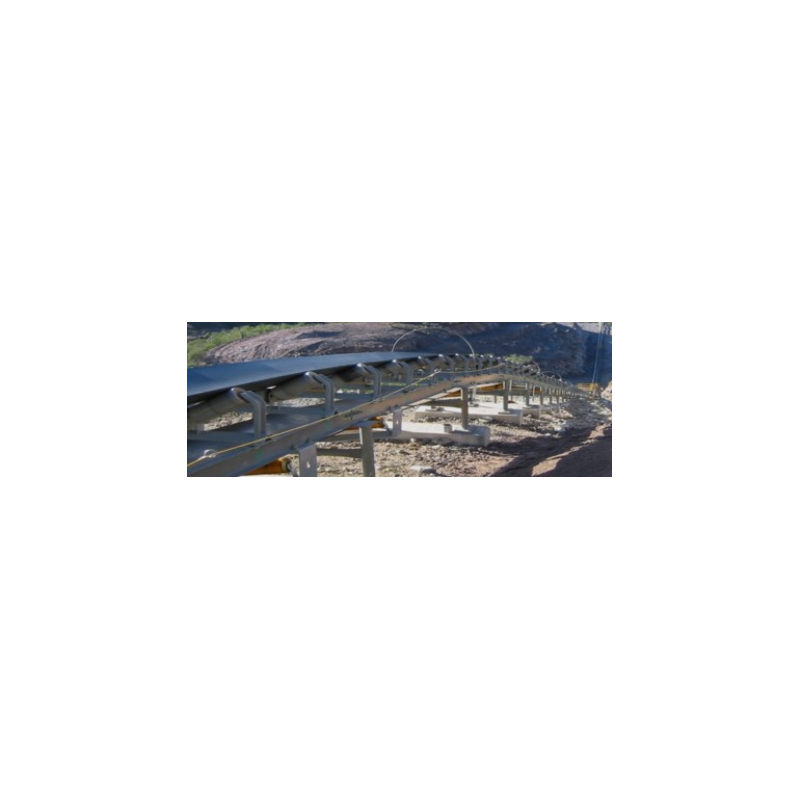

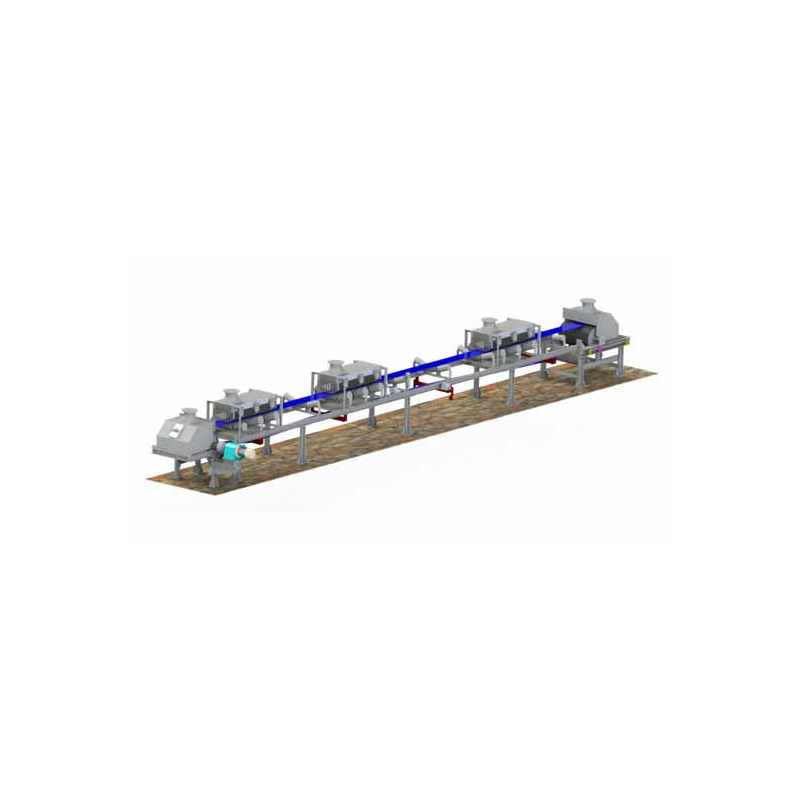

Overland Conveyors

Quantity

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Specifications

| Type | Equipment |

|---|---|

| Usage/Application | Minimise installation site prep and field work Reduce power requirements Reduce transfer points Reduce operating costs |

| Technology | Conveying Material handling |

| Industry | Cement Mining More |

| Product family | Pneumatic dry bulk handling systems |

Key Features

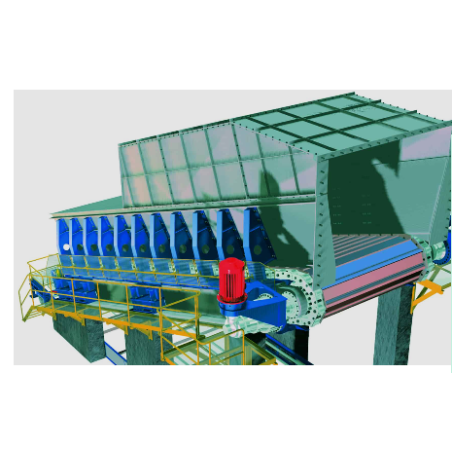

- Design considerations for erection, along with shop pre-assembly, significantly reduce installation fieldwork, and also can reduce the construction schedule. Our conveyor engineers and designers have decades of experience in the field that to help reduce conveyor erection costs.

- By using a combination of head, tail intermediate and booster drives that run only during predetermined demand conditions, our conveyors minimise energy consumption. This results in substantial energy savings and considerable operating cost reduction over the life of the project.

Product Details

Overland Conveyors Varied, isolated terrain can present challenges for overland material transport, including the need for extensive earthwork, multiple conveyor transfer points, and greater power requirements The ability to design conveyors with horizontal and vertical curves means that our cross-country conveyors follow the existing terrain. This greatly reduces the costly earthwork that might otherwise be required to build a long-distance conveyor system. Curves also can eliminate the need for expensive and maintenance-intensive transfers by reducing the necessary number of conveyor segments. They ultimately allow the conveyor to adjust to the topography, rather than making the terrain fit the conveyor.

- We currently have more than 165 Overland Conveyors of greater than 1 km (0.6 mi) in length in operation (the longest of which is 20.3 km (12.6 mi) single flight!). You can turn to us with confidence in designing an Overland Conveyor system that will readily handle your material transport needs.

Other products from this brand

Feeder

Plastic Granules Machine

Pipeline Accessories

Customised Products

Filter Bags

Filter Bags

Conveyors

Conveyors

Recommended Products

Conveyors

Conveyors

Conveyors

Conveyors

Conveyors

Conveyors

Conveyors

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon