Ultrafiltration Membranes

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

- Genuine Products

- Global Shipping

- Secured Payments

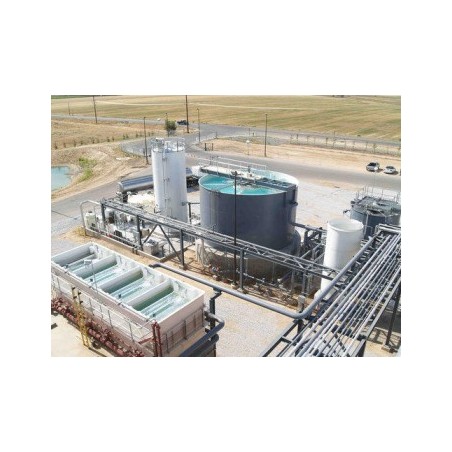

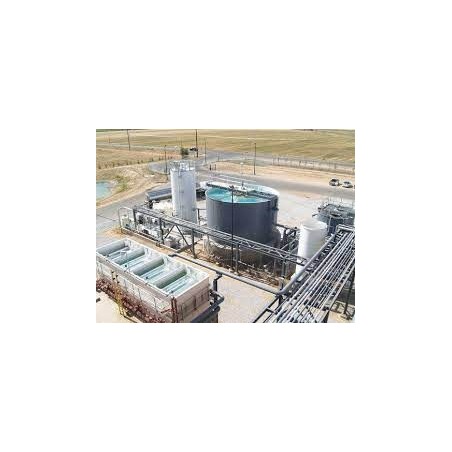

Zero Liquid Discharge(ZLD) Effluent Plant

₹1

Quantity

Specifications

| Country of Origin | Made in India |

|---|---|

| Warranty | 1 Year |

| Automation Grade | Semi-Automatic |

| Installation Type | Prefabricated |

| Water Source | Industrial Effluent |

| Installation Service | Yes |

| Application Industry | Pharmaceutical & Chemicals |

| Control Module | Available |

| Capacity (KLD/MLD) | 1 KLD - 1 MLD |

| Inlet Flow Rate(m3/day or m3/hr) | 1000 m3/day |

| I Deal In | New Only |

| Deliver Type | PAN India |

Key Features

- Lowered waste volumes decrease the cost associated with waste management.

- Recycle water on site, lowering water acquisition costs and risk. Recycling on-site can also result in less treatment needs, versus treating to meet stringent environmental discharge standards.

- Reduce trucks associated with off-site wastewater disposal, and their associated greenhouse gas impact and community road incident risk. Improved environmental performance, and regulatory risk profile for future permitting.

Reference AAJQA Category Zero Liquid Discharge Plant (ZLD Plant)

Product Details

This plant was designed to solve the issue of harmful effluent from a metal processing plant. The metal processing plant had a number of issues with their effluent, including discharge, color, and odors. The ZLD Effluent Plant has been designed to combat these issues by including a series of tanks and pipes. These tanks and pipes are used to separate and purify the effluent. First, the effluent is fed into a series of tanks that use different treatments to remove contaminants. These treatments include activated sludge, sedimentation, and aerobic digestion. Next, the effluent is sent through a set of pipes that purify the effluent by using an advanced filtration system. This system is composed of a number of filters that are designed to remove even the smallest contaminants. The final step in the process is a tertiary treatment. This treatment is designed to further remove any remaining contaminants and make the effluent safe for release into the environment. The ZLD Effluent Plant is designed to be used in the metal processing industry. It is able to remove harmful contaminants from the effluent and make it safe for release into the environment.

- Some processes may recover valuable resources, for example ammonium sulfate fertilizer or sodium chloride salt for ice melting.

Other Products from this Brand

Ultrafiltration Membranes

Thickness Gauge

₹13,785

Oil Skimmer

Dust Collector

Cold Room

Cold Room

Mobile Bio Toilet

Mobile Bio Toilet

Induced Draft Fans

Turbine Blower

Industrial Valves

₹548

Recommended Products

Zero Liquid Discharge Plant (ZLD Plant)

Zero Liquid Discharge Plant (ZLD Plant)

Zero Liquid Discharge Plant (ZLD Plant)

Zero Liquid Discharge Plant (ZLD Plant)

Zero Liquid Discharge Plant (ZLD Plant)

Zero Liquid Discharge Plant (ZLD Plant)