Air Dryer

Reciprocating Air Compressor 5 HP

Quantity

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

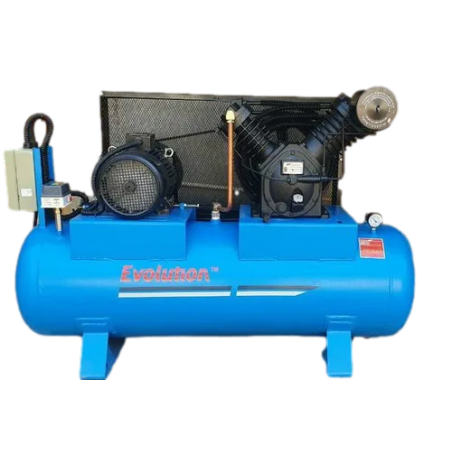

Reciprocating Air Compressor 5 HP

Specifications

| Color | BlackBlueGreen |

|---|---|

| Voltage | 240 |

| Power Source | Diesel AC Three Phase AC Single Phase Electric DC |

| Warranty | 12 Months |

| Current | 240 |

| ACCESSORIES | Dryer Filter Receiver Piping Controls |

| Compressor Type | Gas Compressor Air Compressor |

| Material of Construction | iron |

| Horse Power (HP) | 5 HP |

| No. of Cylinder | 1 |

| Cooling Method | Air Cooled Water Cooled |

| Compressor Technology | Reciprocating |

| Air Quality Standard | Class 4 Class 2 Class 6 Class 3 Class 5 Class 1 |

| Number of Compression Stages | Three Stage Single Stage Two Stage |

| Lubrication Style | Oil FreeOil FloodedOil Less |

| Compressor Mounting Configuration | Skid/Base Plate MountedTrolley MountedTank Mounted |

| Discharge Pressure (in bar) | 4 bar 8 bar 12 bar 7 bar 10 bar |

| Air Tank Capacity (in L) | 300 L 1000 L 220 L 270 L 500 L |

| Maximum Flow Rate (in cfm) | 0-20 cfm 51 - 120 cfm 121 - 500 cfm 501 - 1000 cfm 21 - 50 cfm Greater Than 1000 cfm |

| Weight (in kg) | Depend on size |

| Reciprocating Air Compressor repairs required | yes |

| s It Portable | Portable |

| Rental Available | No |

Key Features

- High quality

- Durability

Product Details

Reciprocating Air Compressor is a positive compressor in which air is sucked in a chamber and compressed with the help of a reciprocating piston which is used by the compressor. It is called positive displacement. Firstly air is sucked in a chamber and then compression air is transferred to the decreasing area by the piston. Which reciprocating motion is decreased by a piston?The reciprocating compressor consists of a piston which is enclosed within the cylinder & equipped with suction & discharge valves.The piston receives power through the crankshaft and connecting rod. A flywheel/belt wheel is fitted on the crankshaft which is connected by the electric motor or diesel engine. The uniform motion throughout the cycle of operations.The compression air is first drawing a volume of air into the cylinder through suction valves during the piston stroke. The compressing & discharging on the return stroke of the piston through delivery valves.This work is used in every Reciprocating Air Compressor. You will easily understand compressor engineering from the below description. The main three types of air compressors are used for industrial works:1.) The Single Stage Reciprocating Air Compressor Works2.) The Double Stage Reciprocating Air Compressor Works 3.) The three-stage air compressors workSingle Stage Reciprocating Air Compressor Works In the single-stage reciprocating air compressor, the entire compression air is carried out by a single cylinder.The compression air is affected in one end of the piston. The cylinder is known as single-acting, the compression air is affected in both ends of the piston, and the cylinder is known as a double-acting reciprocating air compressor.The opening & closing of a simple check valve depends upon the differential pressure, if mechanically operated valves are used for suction & discharge then their functioning is controlled by cams that are on the wheel.Double Stage Reciprocating Air Compressor Works In the double stage or two stages, reciprocating air compressors consist of two cylinders. One is called a low-pressure cylinder and the second is called a high-pressure cylinder.When the piston in a low-pressure cylinder is the outer dead center (ODC) the weight of air inside the cylinder is zero, as the piston moves towards the inner dead center (IDC) pressure falls below atmospheric pressure when suction valves open due to a pressure difference.The atmospheric air is drawn into the low-pressure cylinder through an air suction filter. Air is compressed by the piston and pressure inside & outside the cylinder is equal. When both are equal point suction then valves closed.The three-stage air compressors.Working Principle of Multi-Stage Air Compressor Most industries required air pressure of more than 35 kg/cm to produce their product. For example, a mineral water bottle requires air pressure of more than 40 kg/cm. To produce the desired shape of a bottle at the bottom side and other fields in industrial.In two stages reciprocating air compressor is not useful. We required the air compressor which produces air pressure above 35 kg/cm.Air pressure is released when achieved by a multi-stage air compressor. Now use three-stage reciprocating air compressors as a multi-stage air compressor. If we are required air pressure discharge above 85 kg/cm then four-stage air compressors are useful.

- High performance

Other products from this brand

Air Compressor

Industrial Air Filter

Air Receiver Tank

Air Compressor

Refrigerated Air Dryers

Reciprocating Compressors

Recommended Products

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon