Biogas Generator

Air Compressor 224 RPM

Quantity

5/5

Free Delivery in India | Lowest Global Shipping Charges

- Genuine Products

- Global Shipping

- Secured Payments

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases. And 0% Taxes on all worldwide deliveries

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

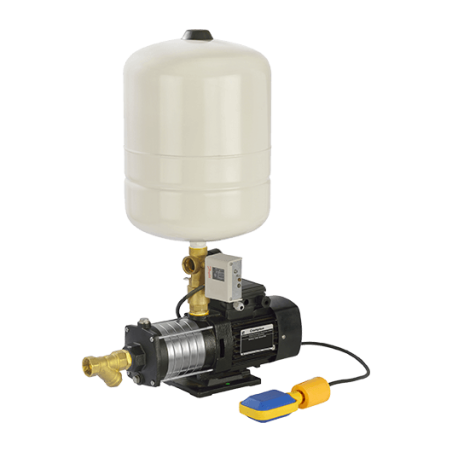

Air Compressor 224 RPM

Specifications

| Automation Grade | Yes |

|---|---|

| Flow capacity | 400 CFM |

| Motor Speed | 224rpm |

| Compressor Type | Wheeled-Carry Compressor |

| Horse Power (HP) | 30 |

| Service Location/City | India |

| Cooling Method | Air Cooled |

| Power Sources | Diesel |

| Compressor Model | As Requirement |

Key Features

- High quality

- Durability

Product Details

The compressed air source for the factory to our easy to understand information on rotary screw air compressors. On this page, I want to tell you about the pros and cons of the rotary screw compressor, what to look for when buying one and common breakdowns that might occur during operation.This is a non-stopping process, this kind of compressor doesnt create a lot of noise; it runs saliently and smoothly. The Compared to piston-type reciprocating compressors to the screw compressor is much more costly. But it has to run 24/7 and 365 days a year without any problems. The capacity of screw compressors is generally much high compared to piston-type compressors.The screw air compressor element was first developed in the 1930s, it has consisted of a male and female rotors. The rotors are of the different shape but fitted each other exactly. When working the male rotor drives then female rotor if its an oil-injected screw compressor technology, and a timing gear drives both rotors in the oil-free compressor technology as both rotors will moving harmonically with minimum calculated clearance between both elements.A rotary air compressor is the best positive displacement compressors. The mostly rotary air compressor is used to the single stage helical or spiral lobe oil flooded screw air compressor. This Type of compressors consists of two rotors and both rotors are casing where the rotors compress the air internally. This type of compressor is not present valves. These compressor units are basically oil cooled, where the oil seals in the internal clearances.Rotary screw air compressors are easy to operate. Capacity control for these compressors is variable speed and variable compressor displacement. The compressor capacity is reduced, When the slide valve opens, bypassing a portion of the compressed air back to the suction. The Best advantages of the rotary screw compressor include smooth and pulse-free air output in a compact size with high output volume over a long life.The oil-free rotary screw air compressor utilizes especially working to air ends to compress air without oil in the compression chamber yielding true oil-free air. Oil-free rotary screw air compressors are available air cooled and water-cooled and provide the same flexibility as oil flooded rotaries when the oil-free air is required.

- High performance

Other products from this brand

Gate Valves

$129

Fire Fighting Pumps

$103

$64

$59

$87

Recommended Products

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Quantity

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

# Lowest Price Challenge

If you find this product anywhere at lower cost than us. Call us and we will not only match the price but also give a complimentary coupon