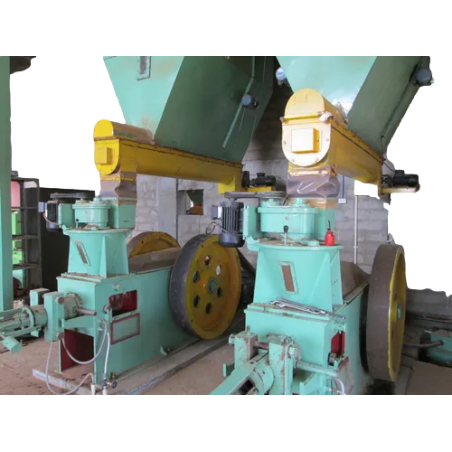

Wood Pellet Machine

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

- Genuine Products

- Global Shipping

- Secured Payments

Wood Pellet Machine 5th & 6th generation

Quantity

Specifications

| Country of Origin | India |

|---|---|

| Warranty | As per Manufacturer |

Key Features

- Bulk Quantities Available

Product Details

The centrifugal high-efficiency Pellet Machine originated from Yulong, and has undergone many core technology improvements and functional improvements since its development in 2010. Now updated to the eighth generation products.Yulong has always mastered the patent and core technology of this product. The appearance of the product is easy to imitate by peers, but the core technology has never been surpassed. The main shaft of the centrifugal high-efficiency pellet machineThe main advantages of the eighth generation pellet machine:1. The main motor is changed to a standard flat key motor, and the German standard KTR elastic coupling is adopted with the reducer, which solves the problem of regular lubricating grease for the spline of the seventh generation granulator. Moreover, the replacement cost of KTR elastomer is much lower than the replacement cost after spline damage.2. The positioning of the spindle frame plate and the spindle has been upgraded and improved, the pin positioning that is not easy to disassemble and easy to wear is removed, and the embedded positioning method of CNC machining is adopted, which is easy to disassemble and not easy to wear.3. Improvement of kick-out system: The reducer of kick-out plate is replaced by a cycloidal pinwheel reducer to a hard-tooth surface reducer. The rotating components of the kick-out system are completely separated from the kick-out boot (the entire driving operation is outside), which completely solves the problem that the kick-out system is susceptible to high temperature steam. Moreover, in the kick-out boot of the pellet machine, except for the kick-out turntable, the rest of the non-moving parts that can contact the material and steam are all made of stainless steel, which fundamentally solves the corrosion problem of metal materials.The main shaft is thickened by 15%, and a new high-rigidity load-bearing structure is adopted to improve the load-bearing capacity and reduce the failure rate of the pellet machineRoller of centrifugal high-efficiency pellet machine The surface of the pressure roller adopts robot surfacing welding wear-resistant materials, which greatly improves the life of the roller. The installation structure of the roller is upgraded to make disassembly and assembly more convenient.Centrifugal high-efficiency pellet machine ring die High wear-resistant stainless steel material, vacuum quenching, ultra-high-speed gun drilling, high-quality hole finish. Use full alloy custom drill bits. The mold is wear-resistant and the service life is increased.Product Testing Three-coordinate detector, gear monitoring center, spectrometer, metallographic microscope, high-precision hardness tester, to ensure that each accessory meets high-precision and high-hardness assembly standardsLaser Cutting The cutting surface of the laser cutting machine is smooth: the cutting surface has no burrs, and the surface roughness of the incision is generally controlled within Ra6.5. It adopts computer programming and modular production and installation.