Thermal Imaging Camera

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

- Genuine Products

- Global Shipping

- Secured Payments

Industrial Online Thermal Imaging Solution For Substation Temperature Monitoring

Quantity

Specifications

| Usage | Power transformers (oil levels and pump operation) Load tap changers (oil levels| other internal problems) |

|---|---|

| Usage/Application | Industrial |

Key Features

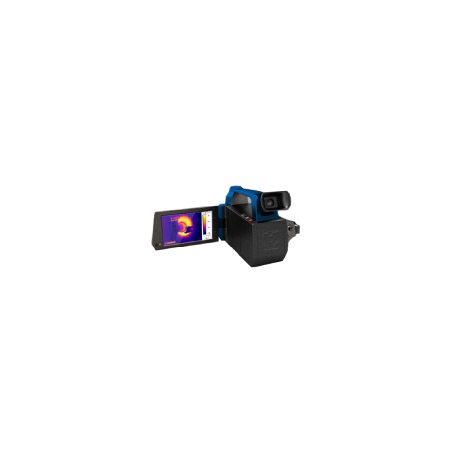

- The first principle of thermal imaging is many components heat up before they fail. Second, all objects emit thermal radiation in the infrared spectrum that is not seen by the human eye.

- Third, thermal imaging cameras convert that radiation to crisp images from which temperatures can be read. This non-contact temperature data can be displayed on a monitor in real-time, and can also be sent to a digital storage device for analysis.

Reference AAWOV Category Thermal Imaging Camera

Product Details

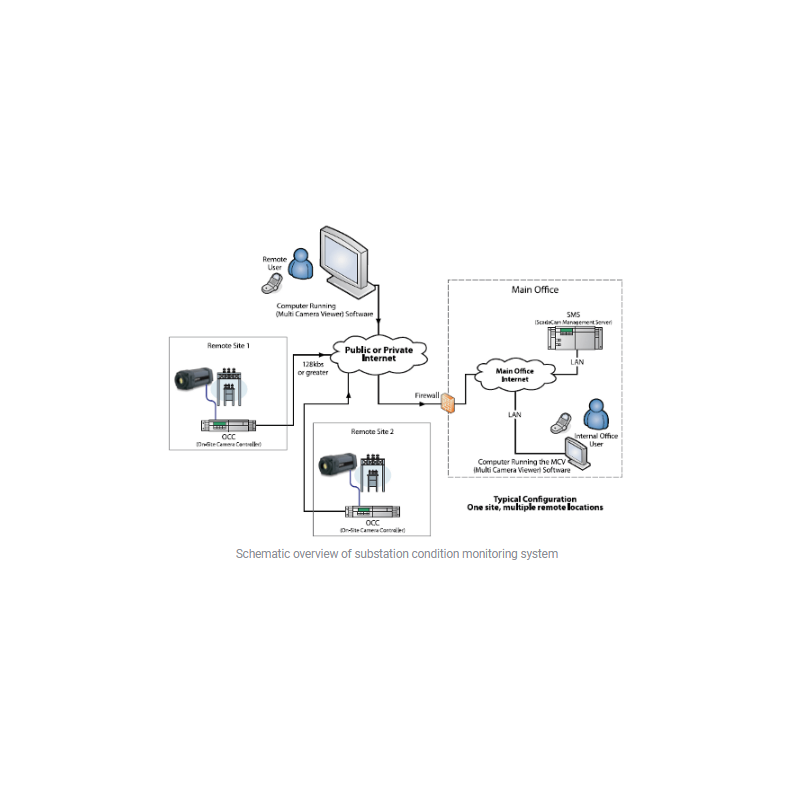

Online Thermal Imaging Solution for Substation Temperature Monitoring Electric power utilities are faced with an aging infrastructure, increasing the risk of blackouts, and brownouts. A brownout is a drop in voltage in an electrical power supply, so named because it typically causes lights to dim. Utilities also face costly unplanned maintenance and rising costs. Utilities are looking for ways to address these issues in order to improve the reliability of electric power delivery while at the same time reducing costs. By using FLIR thermal imaging cameras and automation software, impending equipment failures and security breaches can be detected anytime, day or night, at a remote monitoring location. The net effect is increased reliability and reduced cost.

- FLIR thermal imaging cameras recognize differences in the heat signatures of electrical components and the surrounding background (such as the sky or clouds) and can compare the temperatures of similar components in close proximity to one another. Built-in logic, memory, and data communications allow them to compare the temperatures in their images with user-defined settings, and send that data to a central monitoring station for trend analysis, triggering alarms, and generating exception reports. They can even notify facility managers in remote offices of abnormal conditions by triggering an email message. This makes them ideal for unattended monitoring of substation equipment.

- Thermal imaging cameras do not require light to produce images, and can see hot spots well before excessive heat or loss of insulation leads to failure. They can be mounted in all-weather housings and placed on pan/tilt drive mechanisms to survey large areas of a substation. Due to FLIRs wide selection of lenses with different focal lengths. Therefore, they support 24/7 monitoring in all types of weather and locations.

Recommended products

Thermal Imaging Camera

Thermal Imaging Camera

Thermal Imaging Camera

Thermal Imaging Camera

₹172,518

Thermal Imaging Camera

₹345,038