Material Testing Equipment

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

- Genuine Products

- Global Shipping

- Secured Payments

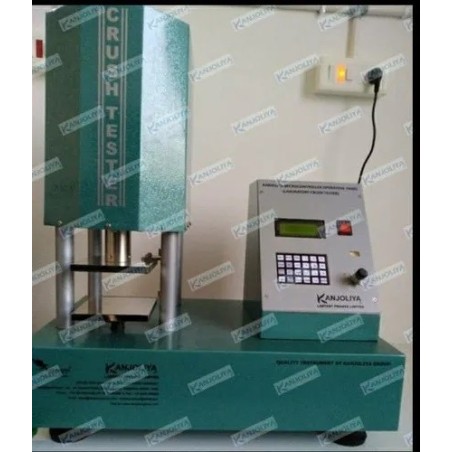

Washbasin / Urinal Load Testing Machine AC220V

Quantity

Specifications

| Power | AC220V 1.0kw |

|---|---|

| Pressure resolution | 10N |

| Use | Toilet wall-hungt wash basin urinal woman washer shower plate Etc. |

| Air cylinder pressure | 0.0-6000N precision 1.0 |

| A/D conversion time | Less Than -250s |

| Cylinder loading force | 0-6000N adjustable |

| Number of stations | 1 |

| Test load accuracy | 0.01 |

Key Features

- High performance

Reference ACAUR Category Material Testing Equipment

Product Details

Washbasin / Urinal Load Testing Machine, The sanitary wares load carrying capacity testing machine adopts an electric platen as sample loading, which is used to test the load-resistant of the sample and the packing box stacking experiment. This equipment is designed and manufactured in accordance with the requirements of GB/ T6952-2005 sanitary ceramics and GB 26730-2011 Gravity flush device and sanitary fixture rack for sanitary wares and toilets. This machine owns the features of simple operation, stable loading, high measurement accuracy, and high automation degree, and is an ideal equipment for carrying out load resistance tests on various sanitary wares and ceramics products.The equipment provided with three different mounting racks and different mounting holes can be selected for different sanitary wares like toilets, wall-hung toilets, wash basins, urinals, woman's washers, shower plates, and other sanitary wares.Install the mounting rack on the sample supporting the lifting platform. The mounting rack can be installed in front and back, and different mounting holes can be selected according to the size of the product under test. Before the test, first, adjust the foot to make the whole machine level, and then according to the requirements of the sign can be connected.System components: pneumatic loading device, mounting frame, sample support lifting platform, laser positioning device, touch control system five major components.(*The working air source of the machine needs to be prepared by users: air compressor or centralized air source)

Recommended products

Material Testing Equipment

Material Testing Equipment

Material Testing Equipment

Material Testing Equipment

Material Testing Equipment