Air Classifiers

100% Original Products

Shop with assurance, as each product we offer is 100% original, ensuring quality and authenticity with every purchase

Save up to 28% with GST Input

Avail maximum benefits from input tax mechanism on all your Business Invoices. Get GST Invoices on your business purchases

24/7 Customer Support

Shop with confidence knowing that our 24/7 Customer Support is always available to assist with any inquiries

- Genuine Products

- Global Shipping

- Secured Payments

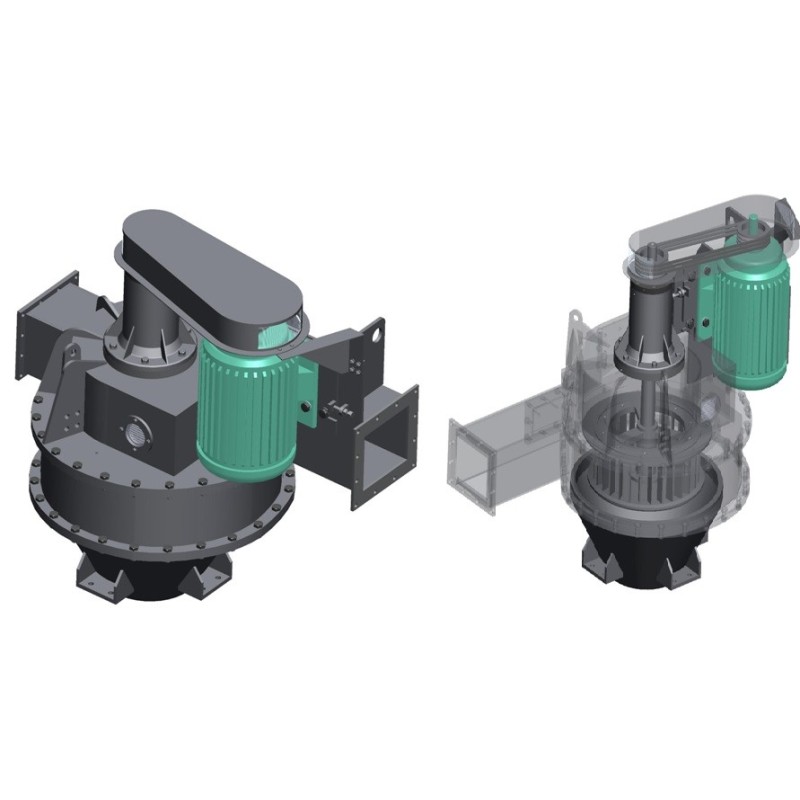

Industrial Air Classifier Mill

Quantity

Specifications

| Country of Origin | India |

|---|---|

| Warranty | As per Manufacturer |

Key Features

- Bulk Quantities Available

Reference AAGGZ Category Air Classifiers

Product Details

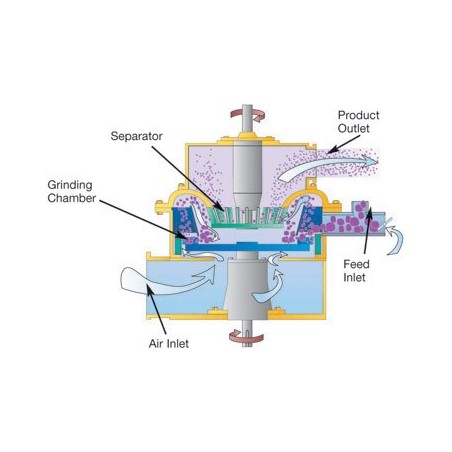

We are instrumental in manufacturing and supplying Air Classifier. The offered instrument is used for separating different sizes of particles from two and more kinds of powdered substances. It makes use of centrifugal force and air currents for separation on the basis of weight of the particles. This machine is built in adherence to the industrial standards. Microniz Air ClassifierOur Micronizing plant consists = feed hopper with screw feeder, Ultra fine air classifier ,,inter-connecting Ducts, Dust Collector (Bag Filter), Blower, Air Compressor and Electric Control Panel with Electric Motors.OPERATION: This unit has specially been designed to serve the purpose of classification of the ground material. The mineral powder of 400/500 mesh size is feed to the hopper through screw feeder which further leads to the classifier unit which classifies the powder in the order of 20 or 10 micron size and the coarse material (i.e. Tailing) is recovered from the bottom of the Air lock. The classifier runs through V Belts drive with the help of Electric Motor. The RPM of the classifier is adjusted through variable frequency drive in order to obtain different micron sizes. The Blower Placed in the circuit pushes the material to the classifier unit for classification of the material as per requirement and then the same goes to the RPJ Dust Collector from where the final product is collector through Air Lock. It is a Continuous process wherein we feed new material with tailing material through screw feeder.

Recommended products

Air Classifiers